What Are the Challenges Faced By the Zhaga Photocell Industry

Introduction

In the lighting industry, the Zhaga photocell sector faces a myriad of challenges. These challenges span from technological hurdles to market dynamics, impacting manufacturers, suppliers, and end-users alike. Understanding and addressing these obstacles are crucial for the sustained growth and innovation within the Zhaga photocell industry.

In this guide, we’ll dissect the key challenges confronting Zhaga photocell manufacturers and stakeholders. From compatibility issues to regulatory compliance and market competition, we’ll discover into the complexities that shape the industry’s landscape. By shedding light on these challenges, we aim to foster a deeper understanding of the Zhaga photocell sector and pave the way for informed strategies and solutions.

Understanding the Zhaga Standard

This standardization framework primarily focuses on defining the mechanical, electrical, photometric, and thermal interfaces for LED luminaires.

Mechanical Interface

The Zhaga standard specifies the physical dimensions and mounting arrangements for various components such as LED modules, holders, and covers. This ensures that these components can be easily interchanged or replaced without requiring significant modifications to the luminaire housing.

Electrical Interface

In terms of electrical connections, Zhaga outlines the requirements for compatibility between LED modules and drivers. This includes parameters such as voltage, current, and communication protocols to enable seamless integration and interoperability between different manufacturers’ products.

Photometric Performance

Zhaga also addresses photometric aspects to ensure consistent light output and quality across different luminaires. This includes parameters related to luminous flux, color rendering, and light distribution to meet specific application requirements and standards.

Thermal Management

Effective thermal management is critical for maintaining the performance and longevity of LED luminaires. The Zhaga standard defines guidelines for heat dissipation, thermal resistance, and temperature limits to prevent overheating and ensure reliable operation under various environmental conditions.

By adhering to the Zhaga standard, manufacturers can streamline the development process, reduce compatibility issues, and enhance the overall reliability and performance of LED lighting systems. It provides a common framework for innovation and interoperability, benefiting both industry stakeholders and end-users alike.

Overview of the Zhaga Consortium

In the world of lighting technology, various companies are constantly innovating and developing new products, each with its own unique specifications and standards. This diversity, while fostering innovation, often leads to compatibility issues and complexity in the market.

Enter the Zhaga Consortium. This collaborative group comprises leading companies in the lighting industry dedicated to establishing common standards and interfaces for lighting components. Their primary objective is to streamline interoperability and promote interchangeability among products from different manufacturers.

At the core of Zhaga’s mission are the defined specifications for components such as LED modules, drivers, holders, and connectors. These specifications encompass parameters like mechanical dimensions, electrical interfaces, and thermal performance. By adhering to these standardized specifications, companies can ensure that their products are compatible and interchangeable with others in the market.

Zhaga’s technical standards also extend to communication protocols, facilitating seamless interaction between lighting components. This includes protocols for wired and wireless communication, enabling functionalities such as dimming, color control, and sensor integration across diverse lighting systems.

From a technical standpoint, Zhaga’s initiatives not only simplify product integration and interoperability but also foster innovation by providing a common framework for developers to build upon. This standardized approach accelerates the pace of product development and enhances the overall quality and reliability of lighting solutions in the market.

Challenges Faced By the Zhaga Photocell Industry

In the lighting industry, the Zhaga photocell technology faces several challenges that hinder its widespread adoption and implementation. These challenges encompass technical, regulatory, and market-related aspects, impacting the growth and advancement of Zhaga photocell solutions.

Technical Complexity

Zhaga photocell systems involve intricate technical components and integration processes. Designing and manufacturing these systems to meet industry standards while ensuring interoperability with various luminaires can be complex and resource-intensive. Moreover, ensuring compatibility across different generations of Zhaga standards poses additional technical challenges.

Interoperability Issues

Interoperability remains a significant concern in the Zhaga photocell industry. With multiple vendors producing photocell components, achieving seamless compatibility among different devices and luminaires becomes challenging. Inconsistent protocols, communication standards, and varying implementation approaches can hinder interoperability, leading to compatibility issues and user dissatisfaction.

Standardization and Regulation

The absence of comprehensive standardization and regulatory frameworks poses challenges for Zhaga photocell technology. While the Zhaga consortium establishes standards for interoperability, broader industry-wide standards and regulations governing photocell performance, safety, and interoperability are necessary. Without unified standards, manufacturers may face difficulties in ensuring compliance and addressing regulatory requirements across different markets.

Market Fragmentation

The lighting market exhibits fragmentation with diverse players, technologies, and application requirements. This fragmentation complicates the adoption of Zhaga photocell solutions, as manufacturers must cater to varied preferences and specifications of different market segments. Additionally, competing technologies and proprietary solutions further intensify market fragmentation, impacting the widespread acceptance of Zhaga photocell technology.

Cost Considerations

Cost remains a significant barrier to the adoption of Zhaga photocell systems. While the technology offers energy-saving benefits and potential long-term cost reductions through improved efficiency and automation, the initial investment and integration costs can be prohibitive for some users. Balancing the cost-effectiveness of Zhaga photocell solutions with their performance and features remains crucial for enhancing their market competitiveness.

Education and Awareness

Limited awareness and understanding of Zhaga photocell technology among end-users, specifiers, and stakeholders pose challenges to its adoption. Educating the market about the benefits, functionalities, and applications of Zhaga photocell systems is essential for driving demand and acceptance. Moreover, fostering collaboration and knowledge-sharing within the industry can help address misconceptions and promote the broader adoption of Zhaga standards.

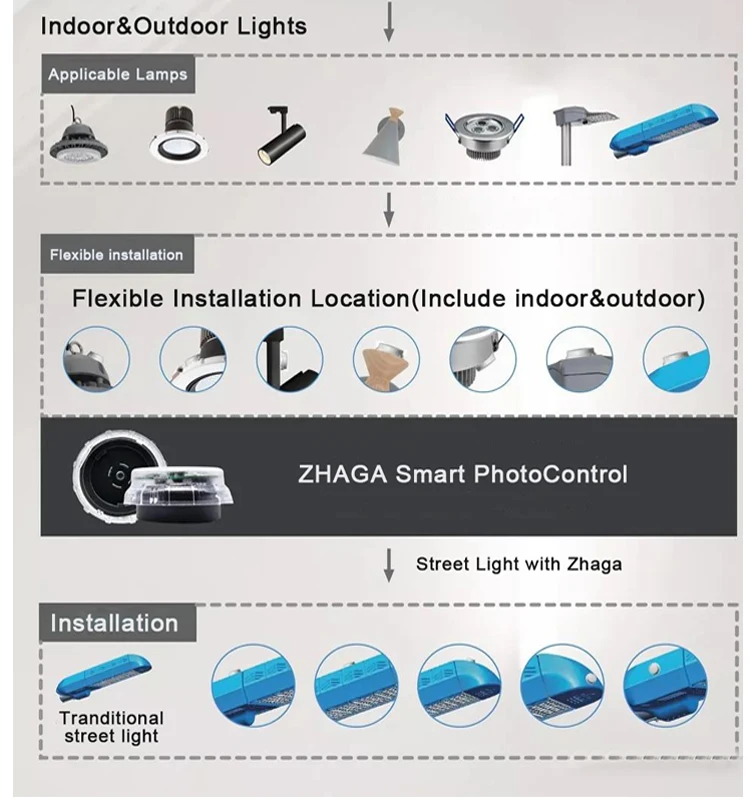

Retrofitting Challenges

Retrofitting existing luminaires with Zhaga photocell technology poses practical challenges due to compatibility issues, installation complexities, and retrofitting costs. Integrating photocell components into legacy luminaires without compromising their aesthetics, performance, or structural integrity requires careful planning and execution. Overcoming these retrofitting challenges is essential for enabling the seamless adoption of Zhaga photocell solutions in retrofit applications.

In summary, addressing the technical, regulatory, market, and implementation challenges is crucial for realizing the full potential of Zhaga photocell technology in the lighting industry. Collaboration among stakeholders, standardization efforts, market education, and technological advancements are essential for overcoming these challenges and driving the widespread adoption of Zhaga photocell solutions.

However, if you want to dive deeper into the world of lighting and stay updated on industry trends, visit us at LONG-JOIN. We’ve got some great insights and resources to help you stay in the know.

Summary

In a nutshell, navigating the Zhaga photocell industry isn’t a walk in the park. From compatibility issues to evolving standards, challenges abound. However, understanding these hurdles is key to overcoming them. Stay ahead by addressing compatibility concerns, adapting to changing standards, and fostering collaboration across the industry.