Analysis Of Differences Between Long-Join JL-240XA, JL-240TXA, And JL-260C Sockets In The Israeli Market

Introdurre

Many engineers and buyers look at JL-240XA, JL-240TXA, and JL-260C and get stuck. They want to know which one fits their site conditions. They also want the one that matches their installation style.

Israel’s mix of hot, dry summers, coastal humidity, and dusty inland areas means that small structural details in a photocontrol receptacle can make a big difference to long-term reliability. In this guide, we break down the three sockets in a simple way. You’ll see what each model is for.

What Are The Core Structural Differences Between JL-240XA, JL-240TXA, And JL-260C?

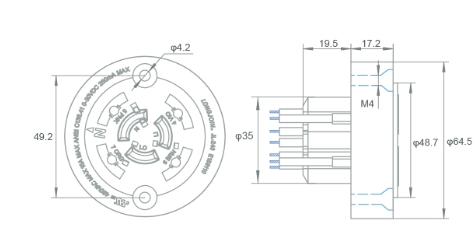

JL-240XA, JL-240TXA, and JL-260C are all 7-wire NEMA sockets built to the ANSI C136.41 standard. But they don’t solve the same mechanical issue. Each one is designed for a different fit, mounting need, or physical setup.

- The JL-240XA comes with a gasket you can remove. It also uses a 7-wire layout. It comes with three power leads. These are usually 14 AWG. It also has four signal leads, which are often 18 AWG. This makes it a flexible in-fixture photocontrol receptacle when you need to fine-tune how the seal sits against the luminaire housing. It’s a classic “install once and rely on it” choice in many Long-Join projects. You can see a full spec breakdown on the JL-240XA product page.

- The JL-240TXA still uses the same 7-wire setup. But it switches to a one-piece, built-in gasket. You don’t have to place the gasket by hand. The socket rear terminal slides in from the front instead. The sealing shape is already built into the design. This targets faster, repeatable installation and more consistent IP performance for dry, dusty, and semi-arid environments.

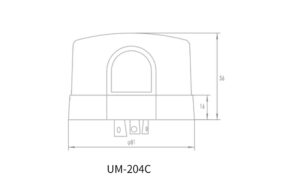

- The JL-260C has a different build. It’s a cable-type receptacle that mounts on the outside. It uses a rotary cable and a metal bracket. The socket is not buried deep inside the lamp body. Instead, it sits outside on a shade, an arm, or a pole bracket. The 7-core cable then runs back into the luminaire.

Key Structural Differences Between JL-240XA, JL-240TXA, And JL-260C

Caratteristica | JL-240XA | JL-240TXA | JL-260C |

Gasket Design | Detachable gasket | One-piece integrated gasket | External sealing with cable and bracket |

Wire Layout | 7-wire (3 power, 4 signal) | 7-wire (3 power, 4 signal) | 7-wire cable harness |

Typical Mounting Position | Inside luminaire / lamp shade | Inside luminaire / lamp shade | Outside shade or on pole bracket |

Space Requirements | Needs precise gasket placement, good for tight spaces | front-insertion, no gasket positioning, speeds assembly | Requires external bracket space and cable routing |

Ideal Use | Flexible sealing, retrofit in varied housings | High-volume, standardized fixtures and mass deployment | Poles, large fixtures, complex outdoor structures |

How Do These Socket Designs Change Installation And Maintenance On Israeli Projects?

In Israel, where crews work in hot weather, tight night-time maintenance windows, and sometimes in dusty or coastal environments, installation speed and repeatability matter almost as much as electrical ratings.

●JL-240XA – adjustable on site

The detachable gasket of JL-240XA gives installers more freedom to adjust how the seal sits.

If a luminaire’s inner surface is not perfectly flat or there is small variation between batches, the gasket can be repositioned or replaced without changing the whole socket. This is useful for retrofits into existing photocell street light heads where mechanical tolerances are not perfectly standardised.

●JL-240TXA – integrated for speed

JL-240TXA targets exactly that scenario. The gasket is built in. The socket rear terminal slides in from the front of the lamp cavity. The installer doesn’t need to line up a separate silicone ring by hand.

This cuts down the assembly steps. For OEMs shipping to Israeli utilities, this helps keep IP performance more consistent across big orders.

●JL-260C – external and service-friendly

JL-260C’s cable-type design and mounting bracket let you place the photocell and node externally, where access is easier.

If the controller or photocell sensor needs replacing, crews don’t have to open the light fixture. They can service the outside assembly instead. This works best on long coastal roads or desert routes.

Why Do NEMA Socket Application Positions Differ Across These Models?

Are you unsure where each socket should sit—inside the shade, on the pole, or externally on a bracket?

The application position is not just a mechanical choice; it also affects how the lighting control system behaves over its lifetime.

●JL-240XA and JL-240TXA – inside the luminaire

Both 240-series models are designed to sit inside the lamp shade or housing.

The ANSI C136.41 nema socket interface is presented at the top, while wiring exits at the back into the luminaire cavity. This is ideal when the design goal is a compact, integrated photocell for street light where the controller twists directly into the top of the lantern with no exposed cable loops.

●JL-260C – outside the luminaire, on brackets or poles

JL-260C is built as an external mounting photocontrol receptacle, with a cable tail that lets you put the NEMA head where it is easiest to reach or where RF coverage is better for smart nodes.

It mounts on steel arms, top caps, or side brackets, then connects back to the driver through the cable. This model is especially useful when the luminaire body itself is crowded with drivers, surge devices, and wiring, leaving no spare flat area for a standard top-mount socket.

Long-Join’s article on Zhaga vs NEMA lighting controls also explains how NEMA top-mount and zhaga socket side- or bottom-mount philosophies differ, which is helpful if you plan to mix standards on the same network.

How Well Do These Sockets Adapt To Israeli Climate And Project Scenarios?

Do you worry that one socket type will work fine in Tel Aviv but struggle in Negev or coastal ports?

Different parts of Israel face dust and heat. Some areas are also humid. Near the coast, the salty air can be corrosive at times. That means the same socket may behave differently in Haifa than it does along a desert highway. The three models give planners options.

Typical Application Scenarios In The Israeli Market

Scenario / Environment | Modello consigliato | Why It Fits |

Coastal cities (humid, salty air, high UV) | JL-240TXA | The built-in gasket and in-fixture mounting seals the unit. It also cuts down long-term leaks and lower the risk of corrosion. |

Desert / semi-arid highways (dust, sand, heat) | JL-240XA or TXA | Internal mounting keeps contacts protected; detachable or integrated gasket suits OEM choice. |

Retrofits on old poles with limited internal space | JL-260C | External bracket avoids cutting new holes or redesigning legacy housings. |

Smart-city pilots with wireless CMS nodes | JL-260C | External mounting can improve antenna exposure and service access for controllers. |

High-volume municipal LED street-light tenders | JL-240TXA | One-piece gasket and front insertion simplify mass production and QC. |

If you need to match sockets with specific photoelectric sensor or controller families, Long-Join’s photocell types and selection guide shows how different dusk-to-dawn heads pair with the 240- and 260-series bases.

For an even wider comparison of NEMA and Zhaga solutions in outdoor lighting, resources from the DALI Alliance on NEMA vs Zhaga-D4i and Schréder’s NEMA and Zhaga systems guide provide extra context on global trends.

What User Value Do Israeli Contractors And End Users Gain From Each Model?

Across all three sockets, the main value comes down to three simple ideas. It’s about efficiency, protection, and flexibility.

●Improved installation efficiency

Which socket helps your teams get more luminaires mounted per night?

JL-240TXA clearly targets fast production and field deployment. Integrated gaskets, front insertion, and repeatable geometry reduce the time each fixture spends on the assembly bench or under a bucket truck.

JL-260C simplifies external mounting where internal space is tight, cutting down rework on legacy poles.

●Enhanced device protection and stability

JL-240TXA has a built-in gasket that keeps steady pressure and helps keep out dust and salty air. This helps it hold its IP seal over time. JL-240XA gives you more room to adjust the fit in tough housings.

●Wide application range and long-term flexibility

Do you want sockets that stay compatible with future control strategies?

All three sockets are meant to host ANSI C136.41-type controllers, from simple photocell switch designs to advanced wireless CMS nodes.

Conclusione

Still unsure which socket to pick for your next tender or pilot?

A simple way to decide is to match one question to each project:

- Need flexible sealing inside varied luminaires?

Choose JL-240XA when you have mixed housing designs, legacy die-cast parts, or you want on-site freedom to adjust gasket placement. - Need fast, consistent builds at scale?

Choose JL-240TXA when you are manufacturing or installing in volume and want integrated gaskets, simpler assembly, and consistent IP performance across the whole line. - Need external mounting and easy service on poles and brackets?

Choose JL-260C when you work on complex poles, high masts, or retrofits where external, cable-type sockets save time and avoid intrusive mechanical changes.

If you’re planning a broader smart-lighting roadmap, you can combine this article with Long-Join’s NEMA vs Zhaga comparison e il Long-Join photocontrol receptacle overview to map sockets, controllers, and future upgrades step by step.

Link esterni:

● https://www.nema.org/standards/technical/ansi-c136-series-standards-for-roadway-and-area-lighting-equipment

● https://www.dali-alliance.org/news/419/tridonic-compares-nema-and-zhaga-d4i-sockets-for-outdoor-lighting

● https://www.schreder.com/en/blogs/nema-and-zhaga-lighting-systems-meet-your-needs