Design Essentials and Technical Realization of Wide Voltage Range Wire-in Photocells

Importance of Wide Voltage Input

Wide voltage input ability is critical for wire-in photocells, permitting the photocell to operate accurately across different grid conditions and regions. With varying electrical standards or unstable power supplies this feature ensures functionality and durability in such environments.

Global Grid Voltage Differences

Manufacturers photocell designs must account for global grid voltage differences. Electrical grids worldwide operate at differing voltages and frequencies. For instance, Europe and Asia rely on 230V/50Hz, while North America primarily uses 120V/60Hz. Wide voltage input photocells usually support ranges such as 85V to 265V AC allowing universal functionality, without any modifications or additional components for regional compatibility.

Adaptation Needs in Areas with Unstable Voltage

In underdeveloped or industrial regions, grid functionality might be characterized by frequent voltage fluctuations. Wire-in photocells with wide voltage range operate reliably in such grid conditions accommodating frequent fluctuations, transients, and power quality issues such as voltage sags below 100V or surges exceeding 250V.

Selection of Wide Voltage Input Power Modules

Selecting power modules optimized for wide voltage ranges is critical for ensuring the photo switch sensor operates effectively in diverse environments, against electrical irregularities, and handles a broad input voltage range along with consistent output. These power modules must consist:

• Voltage range compatibility

• High-efficiency and low standby power

• Thermal management

• Integrated voltage stabilization circuits

• Protection features

Integrated Voltage Stabilization Circuits:

Voltage stabilization circuits are essential in wire-in photocells, to dynamically adjust and regulate power to deliver stable voltage to the sensitive components in photocells. Advanced stabilization ICs, such as those using PWM(Pulse Width Modulation) control the output voltage with rapid changes in input conditions.

Application of High Voltage Tolerance Components

Voltage tolerance components are designed to withstand elevated voltages and transients. Stable output voltage ensures that the photocell’s sensitive electronic components, such as light sensors and control circuits, operate without disruption, even under varying input voltages or load conditions. Linear regulators or switch-mode power supplies (SMPS), adjust the output to remain within a specified range, such as ±1% deviation. Advanced regulators include feedback loops that continuously monitor the output and maintain the desired voltage level.

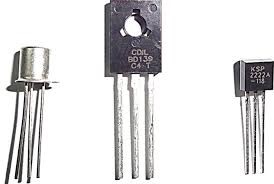

Voltage withstand capacity of capacitors, resistors, transistors

Components such as capacitors, resistors, and transistors have high voltage ratings to tolerate input surges and spikes. The use of X-class or Y-class capacitors ensures safety under continuous operation and transient overvoltage. MOSFETs or IGBTs with high breakdown voltage are chosen for switching and amplification tasks e.g., 600V or higher. High-value metal oxide film resistors with sufficient power ratings are employed to dissipate energy without failure.

Electrical and Thermal Design Verification

Electrical and thermal design verification minimizes the risk of failures caused by electrical overstress or overheating, extending the product’s lifespan and enhancing user confidence. Verify that all components can withstand the maximum input voltage, and perform high-pot testing (Hipot) to validate insulation integrity and resistance to dielectric breakdown. Ensure all components, such as MOSFETs, resistors, and voltage regulators, operate within their specified temperature ratings.

Circuit Design Optimization Strategies

Effective optimization techniques address issues such as voltage regulation, power factor correction, thermal management, and overall system resilience. Optimized circuit designs, including PFC circuits, improve the efficiency and reliability of photocell led street lights, particularly in energy-intensive applications. This multi-stage approach reduces stress on individual components and improves overall efficiency

• Power Factor Correction (PFC)

• Active Voltage Regulation with Feedback Loops

• Efficient Energy Conversion Techniques

• Simulation and Prototyping

All these ensure compliance with global standards, contributing to the photocell’s overall effectiveness and longevity.

Multi-Stage Regulators and PFC Circuits

Multi-stage regulation involves dividing the voltage regulation process into multiple stages, with each stage responsible for specific functions:

• The primary stage handles wide input voltage variations, converting the raw input voltage into an intermediate voltage.

• The secondary stage refines the intermediate voltage, providing a clean, stable, and noise-free output.

Power Factor Correction (PFC) circuits align input current with voltage to improve grid compatibility and reduce losses. Active PFC designs, like boost converters, achieve power factors close to unity, ensuring compliance with standards such as IEC 61000-3-2.

Power factor correction for improved conversion efficiency

PFC improves energy transfer efficiency by reducing reactive power. It is particularly crucial for wide voltage range devices that draw power from grids with varying impedance characteristics. Wide voltage range photocells are often used in regions with unstable or varying voltage levels. PFC helps mitigate losses associated with such fluctuations by ensuring a stable and efficient power draw.

Combined Use of Voltage Regulator ICs and Transformers

These two components work in tandem to ensure that the photocell can handle fluctuating grid voltages and maintain a consistent, stable output for sensitive electronics. In wide voltage range photocells, transformers can handle high input voltages such as 110V or 240V AC and convert them to a level suitable for the system. Voltage Regulator ICs are used after the transformer to precisely regulate the output voltage, ensuring the system receives a stable, consistent voltage.

Stable output voltage

Transformers with appropriately rated windings convert high AC voltages to levels manageable by voltage regulator ICs. These ICs, such as LM2596 or LM317, provide a steady output while filtering noise and ripples.

Accommodation of different grid standards

A wide voltage range photocell must include components like multi-range power supplies or voltage regulation circuits to handle this variability without compromising performance. Galvanic isolation is often employed in the power supply section of wide voltage range photocells, ensuring that the photocell can continue to operate without interference from external grid variations.

Surge and Overvoltage Protection Measures

By integrating MOVs, TVS diodes, SPDs, fuses, and crowbar circuits designers can ensure that photocells remain operational even in surges or fluctuations. Photocell street light designs often integrate MOV varistors and TVS diodes to safeguard against surges and overvoltage. Unlike MOVs, which are typically used to handle larger, short-duration surges, TVS diodes are ideal for handling fast, high-frequency transient spikes.

Integration of MOV varistors and TVS diodes

MOVs are non-linear resistors made from a metal oxide material, such as zinc oxide, which provides resistance that decreases as the applied voltage increases, MOVs are typically used to protect against high-energy transients. TVS diodes are highly effective in protecting against inductive voltage spikes, which may occur due to motors or switching devices.

Automatic power shutdown for overvoltage protection

This protective mechanism acts as a fail-safe to ensure that the system is powered down automatically when the voltage exceeds a safe threshold, thus preventing overstress and long-term damage to the system’s components. This is typically done using voltage monitoring circuits combined with control logic that can interface with power switches such as MOSFETs or relays.

Here is an overview of the technical key-points for wide voltage range wire-in photocontrols

| Aspect | Key Points |

| Importance of Wide Voltage Input | • Operates across global grid voltages (e.g., 85V–265V AC). • Ensures stability in areas with unstable or fluctuating power supplies. |

| Wide Voltage Input Power Modules | • Supports compatibility, efficiency, thermal management, and integrated protection. |

| Voltage Stabilization Circuits | • Maintains consistent output using regulators like LDOs or PWM-based ICs. |

| High Voltage Tolerance Components | • Includes X/Y class capacitors, MOSFETs, and resistors with high voltage withstand capacity. |

| Electrical & Thermal Design Verification | • Conducts high-voltage testing and thermal checks for durability and safety. |

| Circuit Optimization Strategies | • Employs PFC, multi-stage regulation, and active voltage feedback for efficiency. |

| Surge and Overvoltage Protection | • Uses MOV varistors, TVS diodes, and automatic shutdown mechanisms for system safety. |

References

https://en.wikipedia.org/wiki/Low-dropout_regulator

https://en.wikipedia.org/wiki/MOSFET