Precision Selection Guide for Wired Photoelectric Sensor Relays: A Comprehensive Assessment

Introduction

Wired photoelectric sensor relays play a vital role in lighting systems. They enhance energy efficiency and ensure consistent performance. Choosing the right relay is essential for long-term reliability. A poorly selected relay may cause system failures or inefficiencies. This guide focuses on key factors for making the best choice.

Application Scenario Analysis

Operating Environment Matters

Every operating environment has unique challenges. Indoor setups, such as office lighting, require relays with minimal protection. In contrast, outdoor lighting systems face harsher conditions. These include heavy rain, dust, UV exposure, and temperature fluctuations. A photoelectric sensor relay designed for outdoor use must meet stringent protection standards. For environments prone to flooding or high humidity, IP67-rated relays are essential. These relays withstand immersion in water and resist fine dust particles. Always assess the environmental conditions before purchasing a relay.

Load Requirements and Compatibility

The electrical load determines the relay’s capability. For large-scale systems, such as streetlights, high-capacity relays are necessary. These relays handle heavy electrical loads without overheating. In contrast, residential or small-scale commercial systems can use standard-capacity relays. Misjudging load requirements can lead to system failures. An overloaded relay may overheat or even catch fire. On the other hand, underloaded relays might not operate optimally. Understanding your system’s current and voltage demands ensures long-lasting performance.

Product Specifications and Certifications

Voltage and Current Standards

The voltage and current ratings of a relay must match the system it supports. Using a relay with mismatched ratings risks damaging the system. For example, a relay with a 220V limit in a 240V system may fail. Always verify that the relay’s voltage and current specifications meet or exceed the system’s requirements. Over-specification can provide an added safety margin, reducing wear over time.

Importance of Certifications

International certifications like CE, UL, and RoHS signify that a product meets industry standards. These certifications indicate a product’s reliability, safety, and environmental compliance. CE marks are common in Europe, while UL is widely recognized in North America. RoHS ensures the relay contains no hazardous materials. Certified relays provide peace of mind and ensure compatibility with safety regulations.

Functional Requirements

Delay Features for Accuracy

Delays help prevent false activations. For instance, sudden power fluctuations may cause false switching. A relay with a delay function avoids this issue. This ensures lighting operates only when required.

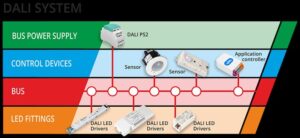

Dimming Options for Flexibility

Some relays come with dimming capabilities. These are ideal for areas with varying lighting needs. For example, parking lots may need brighter lights at peak hours but dimmer lights later. Dimming features allow systems to adjust lighting dynamically.

Durability and Protection Grade

IP Ratings Matter

The IP rating indicates the level of protection against water and dust. For outdoor applications, an IP65 rating ensures waterproofing. Higher ratings, like IP67, protect against temporary immersion in water. Always check the IP rating before purchasing.

UV Resistance for Longevity

Outdoor photoelectric sensor relays face long-term UV exposure. UV rays weaken materials and reduce lifespan. High-quality relays use UV-resistant plastics and coatings. For metal components, anti-corrosion treatments are vital. This prevents rust and degradation over time.

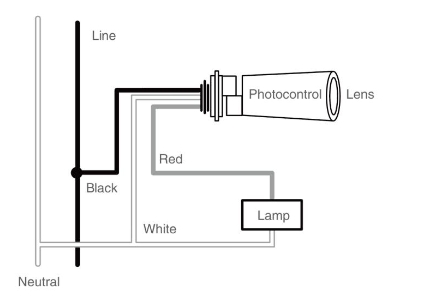

Installation Methods and Wiring Convenience

Simple Installation Saves Time

Relays with pre-labeled wiring are easier to install. Clear labels minimize the chances of wiring errors. Mounting brackets and detailed manuals also speed up installation. These features save both time and effort.

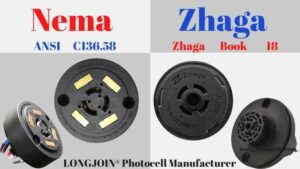

Interface Compatibility

Compatibility between the relay and the system is crucial. Interfaces should align with the system’s connectors. Incompatible interfaces require additional adapters, increasing complexity. Always verify compatibility to avoid delays during installation.

Cost and Brand Selection

Balancing Cost and Quality

Cheaper relays might save money initially. However, they may lack durability or advanced features. Investing in mid-range or premium products ensures better performance. High-quality relays reduce long-term maintenance costs.

Brand Reputation Counts

Established brands provide reliable products. They also offer warranties and better support. Lesser-known brands may lack consistent quality. Choose a trusted brand to ensure peace of mind.

After-sales Service and Technical Support

Value of Technical Assistance

Reliable technical support can solve issues quickly. Support teams assist with troubleshooting and repairs. They also provide guidance during setup and operation. Good support ensures fewer disruptions.

Long-term Benefits

After-sales service plays a key role in maintenance. Timely support reduces downtime and repair costs. Manufacturers offering extended warranties provide added assurance. Strong after-sales service builds trust in the product and brand.

Conclusion

Selecting a wired photoelectric sensor relay requires careful evaluation. Consider the environment and load requirements. Verify product specifications and certifications. Look for additional features like delays and dimming. Choose durable relays with high protection ratings. Ensure installation is straightforward and interfaces are compatible. Prioritize reputable brands with strong after-sales support. Following these steps guarantees a stable and efficient lighting system.

FAQs

What is the most important factor when choosing a wired ohotocontrol relay?

The operating environment and load requirements are critical. These factors ensure the relay matches the system’s needs and functions reliably.

Why are certifications like UL or CE important for relays?

Certifications confirm that the product meets safety, performance, and environmental standards. They ensure quality and reduce the risk of malfunction.

How do IP ratings affect relay selection?

IP ratings indicate the level of protection against water and dust. For outdoor use, higher ratings like IP65 or IP67 provide better durability in harsh conditions.

External Links

https://my.clevelandclinic.org/health/diseases/10985-ultraviolet-radiation