Troubleshooting a Photocell that Does Not Turn The Lights ON/OFF Properly

Introduction

In the lighting industry, ensuring that photocells function correctly is paramount for efficient outdoor lighting systems. When a photocell fails to turn the lights on or off as intended, it can disrupt not only the functionality but also the energy efficiency of the entire system.

Troubleshooting such issues requires a comprehensive understanding of photocell mechanisms and potential underlying factors. From environmental influences to wiring complications, pinpointing the root cause of malfunctioning photocells demands both expertise and systematic troubleshooting techniques.

In this guide, we’ll explore the common challenges associated with photocells that fail to operate properly. By examining troubleshooting strategies and practical solutions, we aim to empower professionals in the lighting industry to address these issues effectively, ensuring optimal performance and energy efficiency in outdoor lighting systems.

Understanding Photocell Functionality

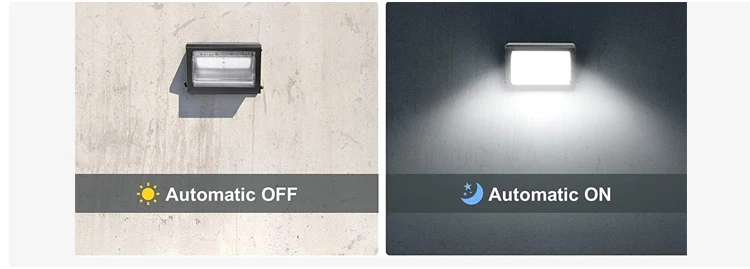

Photocells are made of a special type of semiconductor material. When light hits this material, it excites the electrons within it, causing them to jump to a higher energy state. This jump in energy levels results in a decrease in the resistance of the semiconductor. In simpler terms, when light shines on the photocell, it becomes easier for electricity to flow through it.

Now, the thing is, the amount of light that hits the photocell determines its resistance. So, during the day when it’s bright and sunny, lots of light hits the sensor, causing its resistance to drop significantly. But when it’s nighttime or if there’s less light, the resistance increases because there’s less light exciting those electrons in the semiconductor material.

Typical Issues With Photocell That Does Not Turn The Lights ON/OFF Properly

Here are some common problems you might encounter with a photocell that’s not doing its job properly:

Obstruction or Blockage

Sometimes, the photocell might be obstructed or blocked by dirt, dust, or even foliage. This can prevent it from accurately sensing the light levels and triggering the lights to turn on or off at the right times.

Incorrect Installation Position

The placement of the photocell is crucial for its proper functioning. If it’s installed in a spot where it’s receiving direct or reflected light from the fixtures it controls, it might get confused and not respond as expected. Ensuring it’s positioned correctly can solve this issue.

Wiring Problems

Faulty wiring can also be a culprit. If there’s a loose connection, damaged wire, or improper wiring, it can disrupt the communication between the photocell and the lighting system, leading to erratic behavior.

Environmental Factors

Extreme weather conditions like heavy rain, snow, or excessive sunlight exposure can affect the performance of the photocell. Moisture ingress or excessive heat can damage its components, causing it to malfunction.

Defective Components

Over time, the photocell’s components can degrade or wear out, affecting its sensitivity and reliability. Additionally, if the photocell itself is defective or damaged, it won’t be able to accurately detect light levels and control the lights accordingly.

Interference from Other Light Sources

Sometimes, nearby light sources like street lamps or security lights can interfere with the photocell’s operation. If these sources produce light in the same spectrum as the one the photocell is designed to detect, it can lead to confusion and incorrect responses.

Power Supply Issues

Insufficient power supply or fluctuations in voltage can impact the performance of the photocell. If it’s not receiving the right amount of power, it may not function properly, leading to issues with turning the lights on or off at the appropriate times.

Tools Needed For Troubleshooting Photocell

When you’re dealing with a photocell that’s not turning on properly, there are a few tools you’ll want to have on hand to troubleshoot the issue effectively. Here’s what you’ll need:

Multimeter

First things first, you’ll need a good multimeter. This handy tool will help you measure voltage, current, and resistance in the electrical circuit. It’s essential for pinpointing any abnormalities in the electrical system connected to the photocell.

Screwdrivers

A good set of screwdrivers is a must-have for any troubleshooting job. You’ll likely need them to open up the fixture housing the photocell and access the wiring inside. Make sure you have both flathead and Phillips head screwdrivers in various sizes to tackle any type of screw you encounter.

Wire Strippers

Since you’ll be working with electrical wiring, having a pair of wire strippers is essential. They’ll help you safely remove the insulation from the wires so you can test them properly without causing any damage.

Electrical Tape

Electrical tape is your friend when it comes to securing wire connections and insulating exposed wires. It helps prevent short circuits and ensures that your electrical work is safe and reliable.

Replacement Photocell

If you’ve exhausted all troubleshooting steps and determined that the photocell is indeed faulty, having a replacement on hand can save you time and hassle. Make sure you get the right type of photocell for your specific lighting fixture and application.

Step-by-step Guide To Diagnosing Photocell Problems

Once you have the necessary tools, here’s how to troubleshoot your photocell:

Check for Obstructions

Examine the area around the photocell for any physical obstructions that might impede its light detection capabilities. Ensure that there are no objects blocking its line of sight to the ambient light source.

Verify Power Supply

Inspect the wiring and connections supplying power to the photocell. Use a multimeter to confirm the presence of the expected voltage. Ensure that there are no loose connections or damaged wires compromising the power supply.

Test the Photocell

Perform a functional test on the photocell by covering it to simulate darkness. Observe whether the connected lights respond appropriately by turning on. This test helps determine if the photocell is detecting changes in light levels correctly.

Check Settings (if applicable)

If the photocell features adjustable settings, review its configuration to ensure it aligns with the intended operating parameters. Verify the sensitivity and threshold settings to confirm they match the environmental conditions and lighting requirements.

If problems persist after trying these steps, consider replacing the photocell unit or contact us at LONG-JOIN for more guidance.

Summary

When encountering issues with a malfunctioning photocell, systematic troubleshooting is key. Start by inspecting for potential blockages obstructing the photocell’s view or causing operational interference. Next, delve into the intricacies of wiring connections and voltage levels to ensure optimal functionality. Sometimes, recalibration or adjustments can rectify the issue. Should persistent problems persist, consider a replacement photocell.