The Design Key Points and Difficulties of Zhaga Light Controller Casings and Bases

To ensure the functionality, durability and ease of use, there are a number of key points and potential difficulties the design of Zhaga Photocell casing and bases involve that must be addressed. Some main key points are:

Standardization Compatibility

Zhaga is a global standard for lighting systems. Its book 18 deals with the need for universality of photocell designs. It demands that the bases and cases, sockets and switches etc. be made in a way that they can be used interchangeably no matter what brand they are.

Balancing Size and Functionality

Some of the major aspects of compatibility are those related to the size of the casing, signal compatibility, and structure of connector (such as 4 pin connector 3-pin, 5-pin, 7-pin MENA interface). Ensuring that the standards for these are met can result in better modular interoperability of the photocontrol sensor.

Selection of Materia

The Photocells are to be used in the outdoor setting. Harsh or sudden change in weather conditions can affect the photocells greatly. While selecting the materials for the case of photocells these points should be kept in mind:

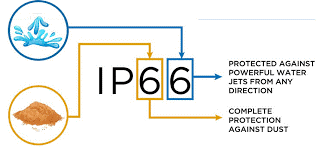

IP66 or Higher Protection Level

To prevent water and dust from entering, the bases and cases must achieve an IP66 or higher protection level, ensuring flawless seal.

Heat Management System

The materials and structures used to design the product should have a proper heat management system such as venting mechanisms or heat sinks.

Electrical Safety

The materials used for the product must be able to house electrical components safely. This way, the risk of short-circuits, electric shocks or fire can be ruled out.

Weatherproof Casing

The casing of the photocell must be weatherproof so that it can survive the wear and tear caused with time due to harsh outdoor weather. The products also need to work with stability under very high or low temperatures.

This can be achieved only by giving extra attention to the details of the materials used in construction of the product and the design of the product. The products can be made water and dust proof by overlapping joints, by using elastomeric materials to seal Gaskets or O-Rings or sealing ports with IP66 or high rated sealed connectors.

UV Resistance

For products used in outdoor setting exposure to sunlight is unavoidable. Considering this, UV Resistance is one of the primary considerations of Zhaga photocell casing and bases.

Some materials, when exposed to UV radiation, can become discolored, brittle or weak over time. Some plastics including PVC can also degrade under UV exposure. UV resistance ensures that the product maintains its appearance and structural integrity over time.

Compact Design and Modularity

To ensure ease of integration, cost efficiency, and flexibility in outdoor light solutions, the emphasis on compact design and modularity in Zhaga photo switch sensor casings and base is very important.

Compact Design:

The Zhaga Photocell casings and bases must be engineered to be compact. This allows more efficient use of space in photocells, in turn helping manufacturers to reduce the overall size of the photocell. This result in a more streamlined product which is aesthetically pleasing as well.

The product should be designed in a way that it can be installed in lamps without affecting the aesthetics of the lamps. It also ensures that the controller is not interfering with the design.

Modularity

For a modular approach, the product should be designed in a way that it can meet the installation needs toof different communication modules as well as sensors. It should also ensure the ease of customization and replacement of components.

Photocells are to be designed in a way that users can mix and match different elements based on their specific needs or upgrades. The flexibility that only the necessary parts can be replaced gives the product its long life and makes its maintenance easier. It is also a cost effective way as it makes it pocket friendly instead of changing the whole system.

Challenges of Multi-functionality

Protection

Despite the compact size, the base must be able to protect sensitive components from external environmental factors such as moisture, dust and temperature fluctuations.

Connection

Efficient internat routing is essential. Designers may use small, flexible connectors or circuit boards to ensure that all components are well connected and are able to communicate effectively.

Signal Transmission

The casing must allow clear, uninterrupted signal transmission between the components. By strategically positioning antennae and using materials that minimize interference this can be achieved.

Efficient use of space

Integrated circuits and other small components must be placed carefully. This will ensure that there is minimal overlap or wasted space.

High Strength and Impact Resistance

Due to the impact of outdoor equipment by people, the casings and bases need to have certain mechanical strength to withstand physical stress in daily use. In addition, the use of high-strength materials should also maintain a balance between cost and weight.

Conclusion

In conclusion, the design of Zhaga light controller casings and bases must carefully balance functionality, durability, and ease of use while adhering to Zhaga standards for compatibility and modularity. Key considerations include selecting weatherproof, UV-resistant, and heat-managing materials to ensure long-term outdoor performance, achieving IP66 or higher protection levels for environmental resilience, and ensuring compactness for aesthetic and space efficiency. Additionally, challenges such as efficient internal routing, signal transmission, and impact resistance must be addressed to create robust and versatile products. By focusing on these aspects, designers can produce high-quality, adaptable, and cost-effective solutions for outdoor lighting systems.

External Link

https://zhagastandard.org/

https://www.sciencedirect.com/topics/engineering/photocell