Enhancing Photocell Production Efficiency: Long-join’s Journey Towards Lean Manufacturing and Intelligent Automation

Introduce

How can we make high-performance photocell sensors in large volumes? Can we do it without losing quality or fresh ideas? At Long-join, that question drives every step of our manufacturing journey. We work in a field where being reliable, precise, and fast matters. So we use lean manufacturing and smart automation to cut waste, speed up production, and boost efficiency. This article shows how our factory floors changed from manual work to smart systems. We kept our core mission: delivering smarter, longer-lasting photocell lighting controls to cities worldwide.

Why Is Optimizing Photocell Production Crucial in Today's Lighting Industry?

The photocell market is growing quickly. It is driven by the world’s demand for energy efficiency, smart cities, and sustainable urban lighting. Photocell sensor makers need smarter ways to build products. They must make their process leaner and adapt quickly to keep up.

Long-join makes smart lighting control parts. It has taken a bold step by adopting lean manufacturing and intelligent automation. This change helps us cut costs. It also makes our products better and lets us respond faster to the growing need for high-performance photocell street lights.

Making photocells isn’t just about numbers. It’s about accuracy, flexibility, and steady reliability. Today, competition is fierce. Businesses with old production systems struggle to meet higher quality standards and faster delivery schedules. Long-join’s strategy ensures customers receive top-tier photocell lighting sensors that perform reliably in even the harshest outdoor conditions.

How Does Long-join Eliminate Waste Through Lean Production?

Waste is one of the biggest hidden costs in manufacturing. It doesn’t just mean trash — it includes lost time, overused materials, unnecessary motion, and defects that could’ve been prevented. For companies like Long-join that produce precision-sensitive components like the photoelectric sensor, reducing waste is critical to achieving high efficiency and profitability.

Here’s how Long-join addresses each of the seven types of waste commonly found in production environments:

Waste Type | Solution Applied by Long-join |

Overproduction | Production aligns with real-time demand using JIT systems |

Waiting Time | Workflow redesign reduces idle machine/operator time |

Transportation | Floor layout optimized to reduce unnecessary movement |

Over-processing | Precision tooling avoids extra work beyond product specs |

Inventory | Forecasting tools reduce excess raw materials |

Motion | Workstations redesigned for ergonomic efficiency |

Defects | Six Sigma and testing checkpoints minimize product errors |

This waste elimination process isn’t just a cost-saving strategy—it’s part of how Long-join delivers reliability. In the world of photocell control, even minor defects can lead to outdoor light failures or reduced lifespan, impacting both customer trust and city infrastructure performance.

What Role Does Continuous Improvement Play in Long-join's Culture?

Small problems often go unnoticed on a busy production floor — until they pile up. That’s where continuous improvement steps in. At Long-join, it’s not just a management buzzword. It’s how operators, line workers, and engineers collaborate every day to refine performance.

When employees are empowered to suggest changes — from adjusting machine settings to redesigning assembly tools — it creates a culture where innovation is constant. This helps Long-join respond faster to customer feedback and adapt quickly to new standards in the lighting control industry.

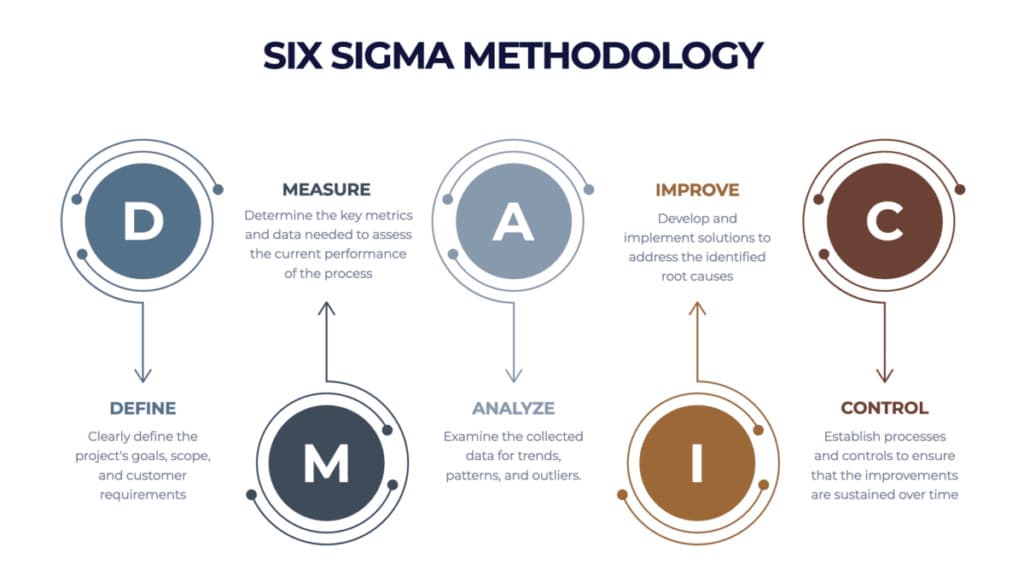

How Does Long-join Apply Six Sigma (DMAIC) to Reduce Defects?

Quality matters more than ever, especially when your products control critical outdoor lighting. A faulty photocell lighting sensor can leave entire streets dark. That’s why Long-join relies on Six Sigma’s DMAIC cycle to root out issues before they reach customers.

Step | Action Taken at Long-join |

Define | Identifying core issues in photocell defect rates |

Measure | Tracking performance using digital sensors and historical defect logs |

Analyze | Root-cause analysis via process mapping and data modeling |

Improve | Equipment upgrades and operator training sessions |

Control | Real-time dashboards to sustain improvements and ensure defect prevention |

By using this structured process, Long-join not only improves consistency but also boosts product longevity — a key factor for anyone relying on dusk to dawn photocell technologies to stay functional year-round.

What New Technologies Help Long-join Improve Process Efficiency?

Innovation in manufacturing often starts with one simple question: How can we do this faster and better? At Long-join, the answer lies in process intensification, using new tools to increase productivity without sacrificing quality.

Modern machines now handle complex tasks with greater speed and accuracy. Long-join uses:

- Laser-guided soldering machines for ultra-precise placement of photocell elements.

- Automated vision inspection to identify surface defects invisible to the human eye.

- Predictive maintenance tools that anticipate machine issues before downtime occurs.

These systems help reduce cycle times and keep quality consistent — essential when producing high volumes of light photocell parts for outdoor systems.

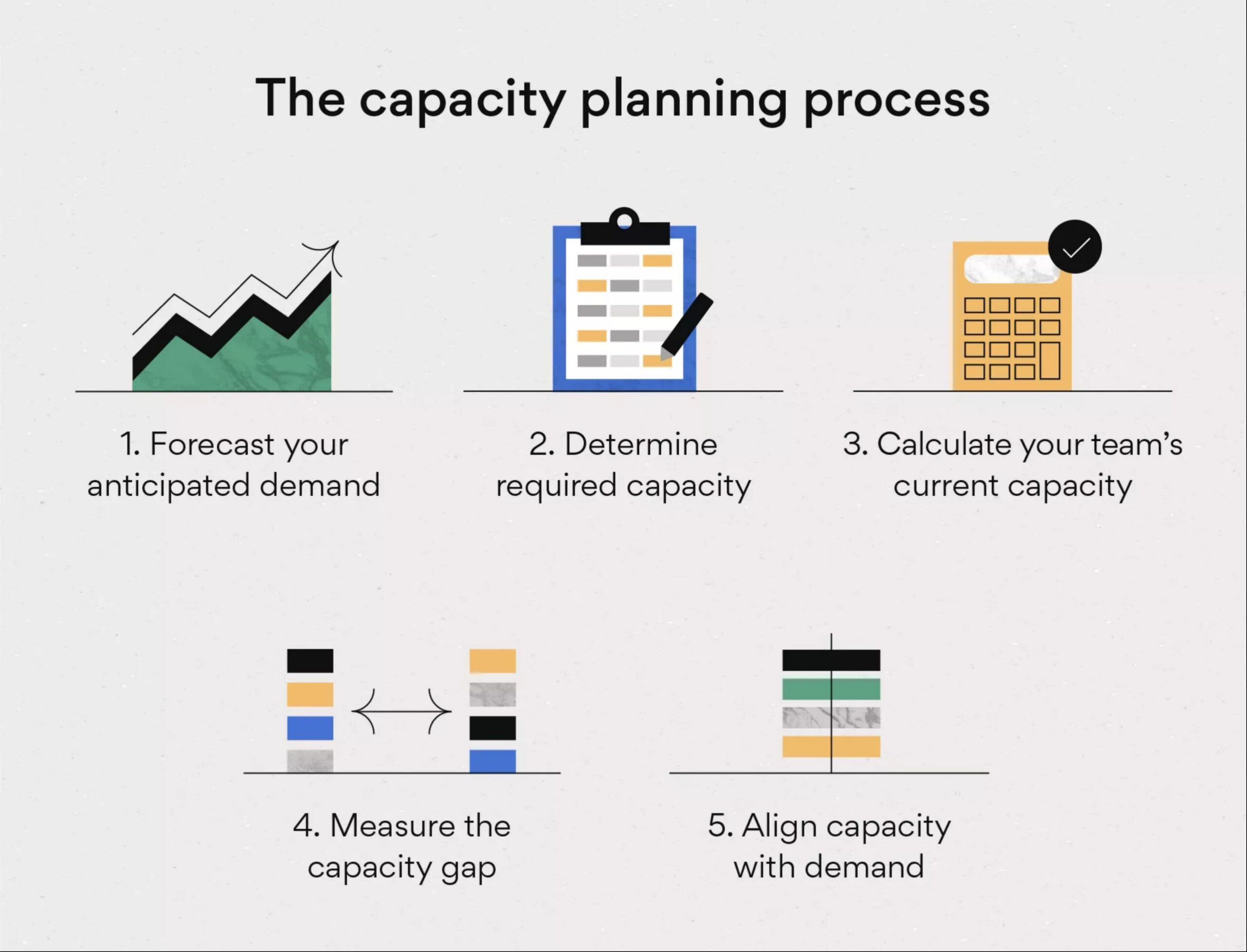

How Does Long-join Handle Capacity Planning Without Overproducing?

Meeting demand without wasting resources is a tricky balance. Long-join relies on capacity planning tools and smart analytics to get it right. When markets shift or order volumes spike, the factory floor adjusts accordingly.

Here’s how it works:

- Demand Forecasting:

- Market signals from photocell for street lightinstallations are tracked using IoT data.

- Reports are shared across logistics and planning teams for fast response.

- Resource Allocation:

- Staff are rotated based on skill level and process priority.

- Machines are utilized in flexible shifts to minimize idle time and maximize output.

This ensures that every watt of power and every square meter of factory space supports only what’s needed — no more, no less.

What is Just-In-Time Production and How Does Long-join Use It?

Just-In-Time (JIT) isn’t just about producing fast — it’s about producing smart. Long-join’s JIT system ensures raw materials are used only when needed, reducing clutter, waste, and delays.

- Inventory Management:

RFID tags track every spool of wire or sensor chip across the floor. Replenishment happens automatically when stock reaches reorder thresholds. - Order-Based Scheduling:

Orders trigger production. So, if a city places an urgent request for photocell switchunits, the system reorganizes production queues to deliver on time.

It’s a smart way to lower costs and raise customer satisfaction.

Why Is Employee Training So Critical in Photocell Manufacturing?

In complex production lines, your machines are only as good as the people operating them. Long-join invests in regular training to help its workforce stay skilled, confident, and accurate.

Technicians learn not just how to assemble components but also how to detect potential problems before they happen. This leads to fewer delays, less rework, and a stronger end product.

It also builds a culture where every worker — whether testing a light sensor photocell switch or calibrating a control board — takes ownership of quality.

How Is Automation Helping Long-join Stay Ahead?

Automation helps Long-join meet high-volume demands without compromising precision. But more importantly, it reduces the physical strain on workers while improving consistency.

Some key tools include:

- Robotic armsfor pick-and-place tasks in photocell board assembly

- MES platformsthat track key quality metrics

- Digital twinsto simulate changes and avoid costly trial-and-error on the line

These tools not only enhance production but also shorten innovation cycles, letting Long-join introduce better, more durable photo sensor solutions faster.

Conclusion

By combining lean principles, Six Sigma strategies, employee training, and cutting-edge automation, Long-join has created a smart, agile photocell production system. These efforts ensure high-quality products, faster delivery, and adaptability to future market demands.

External Links Used

●https://en.wikipedia.org/wiki/Six_Sigma

●https://www.sciencedirect.com/topics/engineering/process-intensification

●https://www.atlassian.com/work-management/project-management/resource-planning/capacity-planning

●https://nl.wikipedia.org/wiki/Just-in-time_(logistiek)

●https://www.gartner.com/reviews/market/manufacturing-execution-systems