How Does the Zhaga Standard Compare To Other Lighting Socket Standards?

Introduction

Within the dynamic realm of lighting technology, the integration of Zhaga sensors into street lighting systems represents a significant advancement. Developed in accordance with the Zhaga Consortium’s rigorous standards, these sensors offer a multitude of technical advantages that are reshaping the landscape of outdoor lighting infrastructure.

As municipalities and urban planners strive to enhance the efficiency, safety, and sustainability of street lighting networks, Zhaga sensors provide a compelling solution. Through precise monitoring and control capabilities, these sensors enable dynamic adjustment of lighting levels based on environmental conditions, occupancy, and other parameters, thereby optimizing energy utilization and reducing operational costs.

In this article, we will explore the multifaceted benefits of Zhaga sensors within the lighting industry. By examining their role in driving efficiency, flexibility, and resilience in street lighting applications, we aim to provide insight into why these sensors are gaining prominence as essential components of modern lighting solutions.

Overview of Various Lighting Socket Standards In The Industry

In the lighting industry, there are different types of sockets used to connect bulbs or lamps to electrical fixtures. These sockets have specific standards set by various organizations to ensure compatibility and safety.

First off, you’ve got the Edison screw base, probably the most widespread one globally. It comes in various sizes, denoted by a letter followed by a number. For instance, E26 and E27 are common in household lighting, while E39 and E40 are larger ones often found in industrial settings.

Then, there’s the bayonet mount, which is quite popular in the UK and some other countries. It’s characterized by a push-and-twist mechanism to secure the bulb.

Next up, you’ve got the pin base, seen mainly in fluorescent and compact fluorescent lamps (CFLs). These come in different configurations like 2-pin, 4-pin, etc., depending on the specific type of lamp.

Now, when it comes to standards, organizations like the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) play a significant role. They set guidelines for socket dimensions, voltage ratings, and other technical aspects to ensure interoperability and safety across different brands and manufacturers.

For example, ANSI has standards like ANSI C81.61 for Edison screw-based sockets, outlining things like dimensions and tolerances. Similarly, the IEC has standards such as IEC 60061 for lamp caps and holders.

It’s worth noting that socket standards can vary regionally due to historical preferences, regulations, and market dynamics. For instance, while the Edison screw is dominant in North America, the bayonet mount is more prevalent in parts of Europe and Asia.

With the rise of LED lighting, there’s been a push towards standardization to ensure compatibility with existing fixtures and to facilitate interchangeability. Organizations like the Zhaga Consortium have been working on developing standardized interfaces for LED modules, promoting interoperability and reducing complexity in the market.

Understanding the Zhaga Standard

The Zhaga Consortium comprises various stakeholders in the LED lighting industry who collaborate to establish standardized specifications for LED components. These specifications aim to facilitate interchangeability among different manufacturers’ products.

Key Components of Zhaga

Mechanical Dimensions: Zhaga specifies the physical dimensions and form factors of LED modules, light engines, and related components. This includes parameters like size, shape, and mounting interfaces, ensuring that products from different manufacturers can be seamlessly integrated.

Electrical Interfaces: Standardized electrical interfaces are crucial for compatibility between LED components. Zhaga defines these interfaces to ensure consistent connectivity and functionality across various products.

Thermal Performance: Effective thermal management is essential for maintaining LED performance and longevity. Zhaga standards address thermal considerations such as heat dissipation mechanisms and allowable operating temperatures to optimize the reliability and lifespan of LED systems.

Benefits of Zhaga Standardization

Interchangeability: Zhaga-compliant components can be easily swapped or replaced without compatibility concerns, providing flexibility in system design and maintenance.

Compatibility: Manufacturers can develop products that adhere to Zhaga standards, knowing that they will be compatible with other Zhaga-compliant devices. This fosters an ecosystem of interoperable LED lighting solutions.

Simplified Integration: Designing LED lighting systems becomes more straightforward and efficient when using Zhaga-standardized components, as they conform to established specifications for mechanical, electrical, and thermal requirements.

Comparison With NEMA Socket Standards: Similarities And Differences

Similarities:

- Electrical Interface Compatibility:

Both Zhaga and NEMA standards prioritize the establishment of a cohesive electrical interface, ensuring seamless connectivity and interoperability among compatible devices. This shared emphasis on electrical standards facilitates consistent performance and reliability across various lighting components.

- Industry Acceptance and Integration:

Both Zhaga and NEMA standards have garnered widespread acceptance within the lighting industry, signifying their utility and reliability in fostering interoperability among different components. This industry-wide adoption underscores their importance as benchmarks for achieving compatibility and standardization.

- Emphasis on Interchangeability:

Zhaga and NEMA standards place a significant emphasis on interchangeability, enabling components adhering to these standards to be effortlessly interchanged or substituted without necessitating extensive modifications. This focus on interoperability enhances flexibility and ease of maintenance for end-users.

Differences:

- Scope and Coverage:

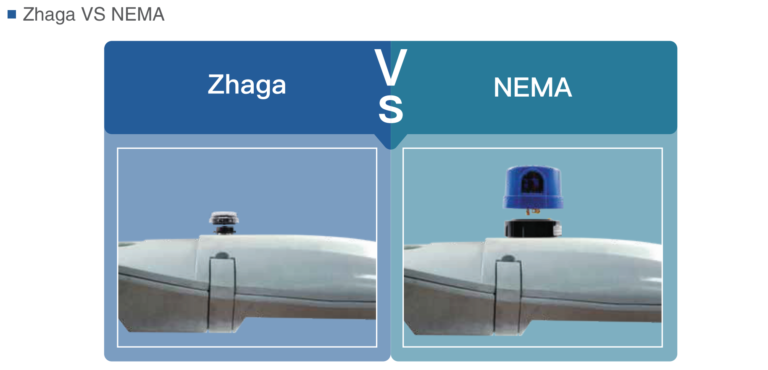

While Zhaga standards predominantly target LED lighting components, encompassing sockets, LED modules, and drivers, NEMA standards have a broader scope, extending beyond lighting to encompass various electrical equipment and systems. This variance in scope dictates the specificity and applicability of each standard within different domains.

- Regional Adoption Patterns:

Regional adoption patterns diverge between Zhaga and NEMA standards, with Zhaga standards witnessing substantial uptake in Europe and Asia, while NEMA standards remain more prevalent in North America. This regional disparity reflects differing market preferences and regulatory landscapes governing lighting technologies.

- Design Specifications and Technical Requirements:

Zhaga and NEMA standards may diverge in their stipulated design specifications, encompassing dimensions, pin configurations, and mounting mechanisms. While both standards prioritize compatibility and interoperability, variations in technical requirements may necessitate tailored approaches to component design and integration.

In essence, while Zhaga and NEMA socket standards share foundational principles of electrical compatibility and interchangeability, disparities in scope, regional adoption, and technical specifications delineate their distinct roles within the landscape of lighting standards.

Contrasting Zhaga Standard With ANSI Socket Standards

The Zhaga standard primarily focuses on standardizing interfaces for LED luminaires, aiming to establish a common protocol for communication and compatibility among various LED components. It encompasses detailed specifications regarding mechanical dimensions, electrical requirements, and communication protocols tailored specifically for LED lighting systems. The Zhaga Consortium, comprised of industry stakeholders, continuously develops and updates these standards to ensure seamless interoperability and interchangeability of LED modules, drivers, and other components.

In contrast, ANSI socket standards, such as those defined by the American National Standards Institute (ANSI), govern a broader spectrum of lighting technologies beyond LEDs. These standards dictate the physical and electrical characteristics of sockets and connectors used in traditional lighting fixtures, including incandescent, fluorescent, and high-intensity discharge (HID) lamps. ANSI standards address factors such as socket size, configuration, voltage rating, and safety requirements to ensure compatibility and proper operation across diverse lighting applications.

Key Differences:

Scope: Zhaga standardizes LED-specific interfaces, while ANSI socket standards cover a wider range of lighting technologies.

Detail: Zhaga standards provide granular specifications for LED components, including mechanical, electrical, and communication aspects, whereas ANSI standards offer broader guidelines applicable to various lighting technologies.

Emphasis: Zhaga prioritizes interoperability and interchangeability within LED systems, whereas ANSI standards focus on compatibility and safety across different types of lighting fixtures.

The Zhaga standard has gained significant traction within the LED lighting sector due to its focus on modularity and interoperability, catering to the evolving needs of the industry. Conversely, ANSI socket standards remain entrenched in traditional lighting applications but are gradually adapting to accommodate advancements in LED technology.

Summary

Unlike other standards that may have limitations or compatibility issues, Zhaga offers a comprehensive framework that promotes seamless integration across various lighting applications. With Zhaga, you’re not just investing in a standard – you’re investing in a future-proof solution that adapts to evolving technologies and market demands. So, when it comes to lighting socket standards, Zhaga emerges as a frontrunner, offering unparalleled flexibility and reliability.

References

- https://en.wikipedia.org/wiki/Edison_screw

- https://en.wikipedia.org/wiki/Compact_fluorescent_lamp

- https://en.wikipedia.org/wiki/International_Electrotechnical_Commission

- https://en.wikipedia.org/wiki/American_National_Standards_Institute

- https://webstore.ansi.org/standards/nema/ansic81612019

- https://std.iec.ch/iec60061

- https://www.e-education.psu.edu/egee102/node/2048