What is The Difference Between NEMA and Zhaga Sockets?

Introduction

If you’re thinking about replacing your lighting system with a smart one, you may be wondering which lighting control socket to use for your installations. The sockets enhance LED luminaires with new functions such as controls and sensors, making lighting smarter. When it comes to choosing the correct lighting sockets for your project, there are several aspects to consider. NEMA and Zhaga are two of the lighting industry’s most regularly utilized standardized sockets. They specify the interfaces and components of LED-based luminaires. They both strive to improve the efficiency, dependability, and sustainability of the lighting system, but their methodologies and features differ to meet the needs of different users.

In this post, we will take a closer look at the NEMA and Zhaga specifications, discussing their features one by one so you can grasp the full image of both these sockets and choose the right one for your building.

What is the NEMA Socket

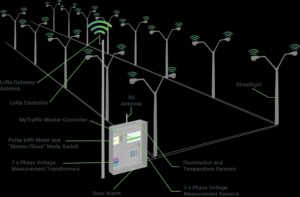

ANSI C136.41 7 PIN Photocell Receptacle JL-260C Supportable Rotate; A NEMA socket by Shanghai Longjoin

NEMA stands for the National Electrical Manufacturers Association, a trade association in the United States that establishes standards for numerous sorts of electrical equipment, including LED-based luminaires. One of the NEMA standards crucial for smart lighting projects is ANSI C136.41, which defines the receptacles and controllers needed to connect and control LED fixtures.

NEMA lighting standards ensure great compatibility and interchangeability among different devices. This means that NEMA-compliant products can be simply incorporated into existing systems, making it easier for manufacturers and end users to pick and install lighting solutions that fit their specific requirements.

Electrical structure

In a NEMA design, the AC mains supply is connected to the receptacle first, allowing the power to flow through the node before reaching the luminaire and its driver. The NEMA controller, which is directly connected to the main supply, is turned on before the luminaire. This technique provides connectivity and a dimming interface for the luminaire control system, together with surge protection, AC/DC low-voltage power supply transformation, energy metering, and load-switching capabilities.

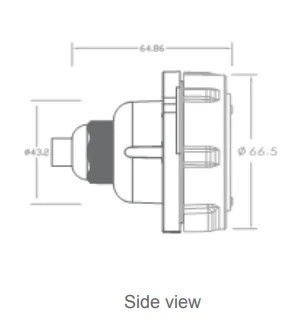

Structure diagram of ANSI C136.41 7 PIN Photocell Receptacle JL-260C Supportable Rotate; A NEMA socket by Shanghai Longjoin

Performance

NEMA standards typically focus on certain product categories and performance measures including lumen output, color rendering index, and fixture life. These requirements are frequently well-established and widely recognized within the industry, making it easier for manufacturers to design and test products that fulfill those standards.

Outer contacts structure

NEMA receptacles and controllers have 3-pin, 5-pin, or 7-pin contacts that serve a variety of applications, including voltage, dimming, and auxiliary power. These contacts include high-voltage wires, which may pose safety issues or necessitate additional safeguards. NEMA receptacles and controllers are also sophisticated and large.

Dimming support

NEMA receptacles and controllers can communicate using analog (1-10V/0-10V dimmable) or DALI protocols. However, analog dimming is not very accurate or dependable, and DALI communication necessitates additional wires or components. NEMA receptacles and controllers are also limited in their compatibility with various LED drivers and sensors.

Auxiliary current

The LED driver’s 7-pin connector (on the orange wire) provides auxiliary power to NEMA receptacles and controllers. However, this capability is not generally supported by LED drivers or sensors, which may result in power loss or instability. NEMA receptacles and controllers do have not many choices for auxiliary power voltage or current.

Reliability

NEMA controllers are meant to connect directly to the power grid’s AC power supply (115V/230V). To power its internal electronics, the NEMA controller converts the AC electricity to DC voltage, which is then passed on to the LED luminaire. However, the NEMA controller’s AC components are prone to breakdown over time as a result of power grid voltage variations and surges. Furthermore, the required AC/DC conversion necessitates several electronic components that are prone to breakdown over time. This leads to NEMA controllers having a shorter design lifetime than Zhaga controllers.

Space requirement

NEMA controllers often have more components than Zhaga controllers, resulting in greater space requirements.

Cost

NEMA controllers often have more components, making them a bit more costly than alternative solutions. When putting a connected-ready luminaire with a NEMA socket but no node, you must utilize an electro-mechanical shorting cap. Without it, the NEMA luminaire will not work properly. However, this extra component increases the system’s price.

Innovation potential

NEMA receptacles and controllers offer limited innovation potential in smart lighting applications. They are based on an ancient conventional norm that has not changed significantly throughout time. They also have limited features or functionalities and do not offer advanced smart lighting capabilities or services.

What is Zhaga socket

It is the current industry standard for street lighting applications, created and backed by the global Zhaga Consortium. This standard originated in Europe and is now widely accepted as the de facto standard in most countries. The last remaining country, the United States, accepted this standard as part of their ANSI C136.58 standard in 2019.

Electrical structure

In a Zhaga architecture, the AC mains supply is connected to the luminaire first, and the Zhaga receptacle is only connected to the driver’s low-voltage auxiliary power supply. As a result, the driver of a Zhaga luminaire has more features than a standard driver, such as improved surge protection, auxiliary power supply, energy metering, and diagnostics. A Zhaga-certified controller, on the other hand, is more simple because it is not powered by the mains.

Performance

Zhaga standards tend to emphasize more customizable performance requirements, such as mechanical dimensions and electrical properties. This enables greater customization and creativity in LED lighting design, but it can also make it more difficult to compare and assess various products based on their performance.

Outer contacts structure

Zhaga sockets and controllers use 4-pin contacts for various functions including voltage, dimming, and auxiliary power. These contacts do not involve high-voltage wires, making them safer and easier to operate. Zhaga plugs and controllers are very compact and attractive.

Dimming support

Zhaga sockets and controllers support DALI connectivity by default. DALI communication is more accurate and dependable than analog dimming because it requires no additional wiring or components. Zhaga sockets and controllers are also very compatible with a variety of LED drivers and sensors that meet DALI specifications.

Auxiliary current

Zhaga sockets and controllers automatically deliver supplementary power from the LED driver on pin 1. This functionality is extensively supported by LED drivers and sensors that adhere to Zhaga or DALI standards, ensuring power efficiency and stability. Zhaga sockets and controllers also provide flexible auxiliary power voltage or current options.

Reliability

Zhaga controllers have a substantially longer lifetime and dependability since they employ a DC input and do not require AC/DC conversion. In contrast, NEMA devices necessitate AC/DC conversion for both the driver and the controller, increasing the number of components and decreasing dependability.

Space requirement

Zhaga controllers are often significantly smaller than traditional NEMA controllers, half or one-third the size. This is partly because Zhaga controllers use many fewer components, such as eliminating the requirement for AC/DC conversion and power-metering circuits.

Cost

Zhaga controllers are often less expensive components because they do not require an AC/DC converter or a metering circuit. In comparison, a Zhaga luminaire could be more costly since it necessitates a higher powerful driver. When putting a connected-ready luminaire with a Zhaga socket without a node, a basic mechanical cap will safeguard the socket. After installing a Zhaga-D4i controller on the street light, the cap is readily removed.

Innovation potential

Zhaga sockets and controllers have a high level of innovation possibilities for smart lighting. They are founded on a modern industry standard that evolves and improves over time. They also contain numerous features or functionalities that enable expanded capabilities or services for digital lighting applications such as data collecting, asset management, and dynamic control.

Conclusion:

In conclusion, choosing between NEMA and Zhaga sockets for your lighting project involves careful consideration of various factors. If compatibility, interchangeability, and adherence to well-established industry standards are crucial, NEMA provides a reliable but less flexible option. On the other hand, if you prioritize innovation, adaptability, and a smaller form factor, Zhaga stands out with its modern approach, lower cost, and higher reliability. Ultimately, the decision depends on your specific project requirements, with NEMA offering a solid foundation and Zhaga opening doors to the future of smart lighting technologies.

The best way to choose the right type of socks is by discussing your unique situation with experts. So, just contact us at Shanghai Longjoin here and our team of experts will guide you accordingly.