Interpretando a nova norma UL773 - Atualizações de segurança para fotocélulas externas e seu impacto nos fabricantes

Introduzir

Em ruas, parques e edifícios em todo o mundo, os sistemas de iluminação externa dependem de um componente pequeno, mas essencial: a fotocélula (ou fotocontrole). Este pequeno dispositivo é o "cérebro" dos sistemas do anoitecer ao amanhecer: acende as luzes ao anoitecer e apaga ao amanhecer. Como engenheiros de iluminação e fabricantes de fotocélulas sabem, sua segurança e confiabilidade impactam diretamente a eficiência energética e a disponibilidade do sistema.

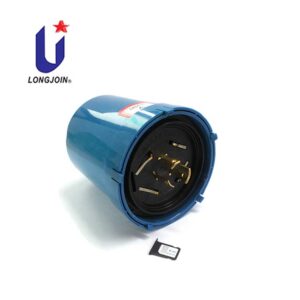

Com o lançamento da atualização UL 773 Com base no padrão de segurança, mudanças importantes já estão em vigor e afetarão a forma como os sensores de iluminação fotocélula para ambientes externos são projetados, testados e certificados. Como líder do setor com certificação UL, a Long-join oferece insights sobre o que mudou, como se adaptar e por que isso é importante para todos os fabricantes envolvidos na produção de fotocélulas para iluminação pública.

O que mudou na UL 773 e por que isso é importante para a segurança?

O IPX4 significa proteção total contra respingos de água de todas as direções — ao contrário da cobertura limitada da zona de respingos do IPX3. Em condições climáticas extremas, esse nível de proteção impede falhas em caixas, cabos e costuras causadas pela chuva. Atualizando para IPX4 afeta tanto o projeto do invólucro do sensor da fotocélula de luz quanto a estratégia de vedação.

Tabela de diferenças principais:

Avaliação | Nível de proteção | O que precisa mudar? |

IPX3 | Jato de água até 60° | Junta simples, protetores de gotejamento de carcaça básica |

IPX4 | Resistência à pulverização de água de 360° | Costuras de fechamento firmes, melhores materiais de vedação, moldagem de precisão |

Os fabricantes devem revisar a espessura do invólucro, o posicionamento da junta e os pontos de entrada do cabo para atender a esses novos requisitos.

E quanto às melhorias na segurança térmica e contra incêndio?

A faixa de temperatura operacional é dobrada: de –35 °C a +65 °C até –40 °C a +70 °C. Agora também há testes de ciclo térmico — para simular oscilações reais de dia e noite ao longo dos anos — e classificações mais rigorosas de retardante de chamas para plásticos. Isso significa escolher materiais com classificação mais alta para UL 94 e projetar placas e invólucros de controle de fotocélulas que não se deformam ou inflamam sob estresse.

Como os padrões de segurança elétrica e proteção contra surtos evoluíram?

A norma agora exige testes de proteção contra surtos, continuidade de aterramento aprimorada, maior separação de isolamento e testes de surtos dedicados à carga de LED. Por quê? Porque os LEDs causam maiores correntes de partida e picos de tensão. Para qualquer interruptor de fotocélula ou interruptor de fotocélula de sensor de luz, agora você deve verificar a compatibilidade com sistemas de LED e adicionar circuitos de proteção contra surtos como padrão.

Como essas mudanças afetarão os roteiros de produtos dos fabricantes?

As linhas de comutação existentes exigirão:

- Atualizações do sistema de vedação: melhores invólucros para sensores de iluminação de fotocélulas ou cabos sobremoldados

- Melhoria da qualidade do material: Plásticos UL 94‑V0 para climas de alta temperatura/úmidos

- Redesenho do circuito: diodos de surto mais fortes, capacitores de isolamento, reforçados PCB distâncias de fuga

Esses não são ajustes superficiais — eles representam decisões de engenharia significativas e potenciais aumentos de custos.

Como é o processo de certificação atualizado?

A certificação agora inclui:

- Ciclagem térmica e envelhecimento por umidade

- Testes completos de entrada IPX4

- Teste de compatibilidade de surtos de LED

- Testes de continuidade, falha à terra e ruptura de isolamento

Os ciclos de certificação podem levar de 25 a 40% a mais. Os fabricantes devem planejar com antecedência e envolver os laboratórios proativamente para minimizar atrasos.

Quanto custará e como as empresas devem responder?

Redesenho, novos testes e aquisição de materiais podem aumentar o custo por unidade em 5 a 15%. Mas uma preparação estratégica pode reduzir o impacto total. Um plano em fases — priorizando os SKUs de maior volume — além de estabelecer contato antecipado com laboratórios aprovados pela UL, pode economizar tempo e cerca de 30 a % em custos de testes, como mostram nossas estimativas internas.

O que torna o Long-join pronto e vantajoso em comparação aos concorrentes?

Há dois anos, nossa equipe começou a monitorar as revisões do rascunho da norma UL-773. Realizamos análises de lacunas em toda a nossa linha de produtos e a prototipagem começou cedo. Essa previsão nos permitiu responder mais rápido do que a média dos fornecedores de iluminação pública com fotocélulas.

Como nossa linha de produtos atual é compatível com novos requisitos?

Todos os modelos de fotocélulas — séries JL‑207 e JL‑208 — agora atendem:

- Fachada à prova d'água IPX4

- Operando até +70 °C com moldagem retardante de chamas

- Proteção contra surtos integrada para sistemas LED de 120-480 VCA

Também trabalhamos com a UL em revisões pré-auditorias, reduzindo o risco de conformidade.

O que os clientes da Long-join podem esperar durante a transição?

Oferecemos suporte aos clientes com:

- Avaliações de atualização de modelo gratuitas

- Fornecimento duplo de versões legadas e compatíveis com UL-773 durante a transição

- Documentação de conformidade atualizada e relatórios de teste certificados pela UL

- Webinars de treinamento, suporte a produtos e guias de integração

Estamos comprometidos com a integração perfeita, garantindo que não haja interrupção no aproveitamento da luz natural ou nos cronogramas de iluminação pública.

Quais tendências mais amplas do setor estão impulsionando esses padrões de segurança?

Cidades inteligentes exigem confiabilidade. Falhas em loop ou riscos de incêndio não são mais aceitáveis. A UL-773 reflete requisitos mínimos mais rigorosos, alinhados às tendências globais de Soquete Zhaga, Receptáculo NEMA de 7 pinose outras interfaces padrão, aumentando a qualidade do produto em todos os níveis.

Como a integração de sensores inteligentes está evoluindo em relação à conformidade de segurança?

A convergência da indústria significa que mais controladores inteligentes de iluminação pública incluem IoT, diagnóstico remoto e programação de dimerização. Novos padrões podem em breve abranger segurança cibernética, criptografia de dados e interoperabilidade, combinando controle de fotocélulas com infraestrutura conectada.

As mudanças no padrão UL podem influenciar a harmonização global?

As atualizações da UL frequentemente informam os padrões IEC. Isso significa que as atualizações da UL-773 podem em breve servir como referência global para fornecedores de sensores fotoelétricos e fotocélulas com certificação Zhaga em todo o mundo.

O que os fabricantes devem fazer agora? (Recomendações práticas)

- Audite todos os SKUs de produtos em relação aos critérios IPX4, térmicos e de surtos.

- Desenvolva um plano de reformulação em fases, começando com os modelos de maior volume.

- Entre em contato com laboratórios aprovados pela UL e comece a realizar novos testes o mais rápido possível.

Como as empresas devem planejar os fluxos de trabalho de certificação?

Crie uma tabela de cronograma de certificação como abaixo:

Fase | Ações | Linha do tempo |

Análise de Lacunas | Revisar unidades existentes | 1 mês |

Protótipo e Teste | Unidades redesenhadas testadas em testes | 2–3 meses |

Certificação | Enviar para UL | 1–2 meses |

Suporte ao cliente | Documentação, fornecimento duplo | Transição em andamento |

Quais critérios são importantes ao escolher um fornecedor de fotocélulas?

Prefira empresas com:

- Conformidade comprovada com UL 773

- Processos de fabricação transparentes

- Forte suporte técnico e assistência de atualização

- Histórico de compatibilidade de iluminação pública com sensor fotocélula LED

Long-join atende a todos esses critérios.

Por que a Long-join deve ser sua parceira nessa transição?

Graças à nossa P&D proativa, histórico com a UL e presença global em mais de 60 países, somos ágeis, certificados e altamente técnicos no segmento de sensores de luz fotoelétrica para ambientes externos.

Como podemos garantir que sua transição seja tranquila?

- Treinamento contínuo e webinars de conformidade

- Fichas técnicas detalhadas claramente identificadas como “compatível com UL 773”

- Guias de integração para Soquete Zhaga, Receptáculo NEMA de 7 pinos, e interfaces de controlador inteligente

Qual é o nosso compromisso daqui para frente?

Padrões mais elevados levam a soluções mais inteligentes. A Long-join se dedica a elevar o padrão, tornando o seu do anoitecer ao amanhecer sensor de fotocélula sistemas mais seguros, inteligentes e confiáveis.

Conclusão e lista de verificação de prioridades do cliente

Essas atualizações da norma UL-773 representam um ponto de virada para os produtos de controle de fotocélulas. Embora adicionem complexidade, também criam oportunidades: seus produtos agora podem liderar em mercados onde confiabilidade e segurança são inegociáveis.

O que você deve fazer imediatamente?

- Auditar SKUs para verificar lacunas de conformidade

- Comece a redesenhar e prototipar

- Agendar testes de laboratório UL

- Alinhe-se com um fornecedor certificado como a Long-join

- Comunique-se de forma transparente com seus clientes e parceiros

Agindo agora, os fabricantes podem evitar atrasos, controlar custos e sair mais fortes — e a Long-join está pronta para ajudar você em cada etapa.

Links externos:

●https://www.intermatic.com/Product/K171H?setcontextlanguagecode=en

●https://www.zgsm-china.com/blog/nema-vs-zhaga.html

●https://en.wikipedia.org/wiki/Printed_circuit_board

●https://phiaton.com/blogs/audio/ipx4-water-resistance-o-que-significa-e-por-que-voce-precisa-disso?srsltid=AfmBOoqH8KKCyjxZ7l3a6YH4jURR2pF-qjAa1xnSdp9DvCyGfhL5dhkP