لماذا تُعدّ الأسلاك المعتمدة من UL مهمة في أنظمة التحكم الضوئي - ضمانًا للموثوقية على المدى الطويل والامتثال لمعايير السوق العالمية

يقدم

Outdoor lighting is getting smarter and safer. It saves more energy. To keep up, follow global safety rules. UL certification is now a must for customers worldwide. Many makers push product-level UL certification for photocontrols. Few stress certified internal wiring, a hidden part that is still truly critical today.

At Long-Join Electronics, not only are all our photocontrols UL-listed as complete units, but also every wire we use inside our controls is UL-certified—giving our customers end-to-end assurance from plug to PCB. (Check our “Wire-Control Series” at the Long-Join website.

What Is UL 1015 Wire – And Why Is It So Important?

UL 1015 is one of the most common internal wiring standards used in appliance wiring and control systems. It covers a PVC-insulated hook-up wire. Ratings: up to 600 V AC, 750 V DC, and 105 °C max in air.

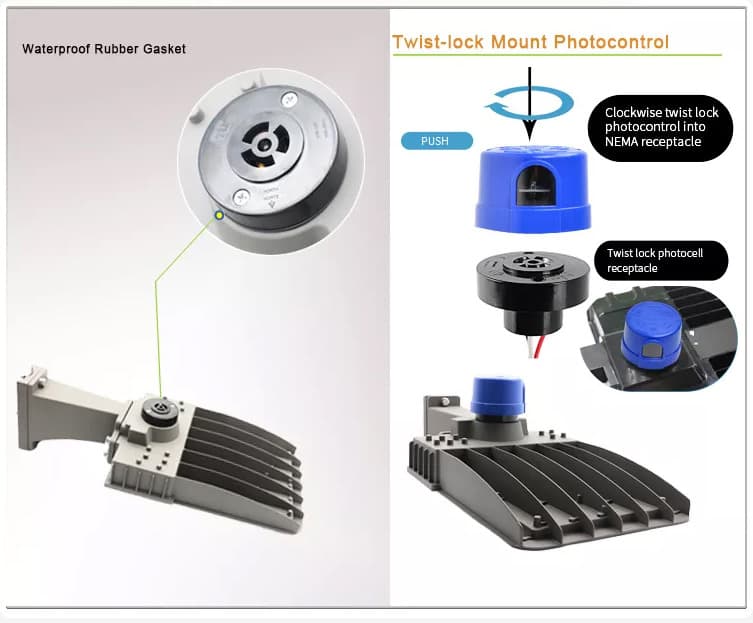

When you set up a light with a dusk-to-dawn photocell, the wiring stays hidden. If the sensor sits in the fixture, it stays hidden. But hidden does not mean safe. If the wiring fails early—from heat, vibration, oil, or flame spread—you face costly warranty claims, serious safety incidents, and even rejected shipments at customs.

Key specifications at a glance:

Because a reliable photocell switch, photoelectric sensor or light control photocell must survive not only ambient external conditions (rain, sun, humidity) but internal heat from the ballast or LED driver, the internal wiring standard becomes critical. If the wire insulation degrades, it may expose conductors, short, degrade insulation resistance—and compromise the entire photocontrol or street light controller.

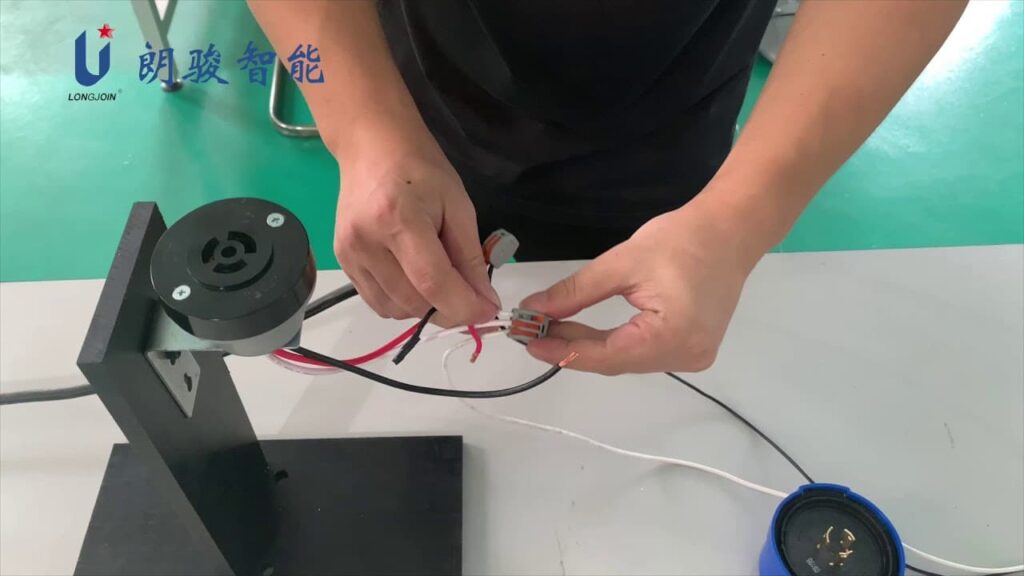

How Does Long-Join Integrates UL-Certified Wiring Into Photocontrols?

At Long-Join, every photocell (e.g., JL-103, JL-245, UM-205C) includes internal wiring strictly compliant with UL Style 1015 (or equivalent) and is fully UL-listed as a complete unit. See our listing details of UL-773A and other approved standards.

Here’s why that matters:

- High-temperature tolerance– Outdoor lighting fixtures often see elevated internal temperatures (LED drivers + ambient heat). UL 1015 ensures the wire insulation can handle those conditions reliably.

- Stable dielectric strength– For AC loads (120V, 208V, 240V, 277V) used by outdoor photocontrols, the wiring must maintain integrity under voltage stress.

- Flame retardant construction– In case of thermal runaway or fault, the wiring must resist flame propagation to protect the housing and entire fixture (important for UL listing under product standard such as UL 773A).

- Traceability and component safety – By using only UL-certified internal wire, Long-Join demonstrates full-scope safety compliance from internal wiring to housing to final product listing.

Table 2: Integration checklist for a UL-certified photocontrol

خطوة | What Long-Join does |

Choose UL Style 1015 wire supplier | Uses supplier with UL file e.g. E527994 |

Mark wire appropriately | Wire printed with “STYLE 1015” and UL file info |

Ensure wire bundling & routing | Internal routing avoids conductor chafing |

Test for vibration & heat cycling | Ensures long-term reliability in outdoor use |

Include documentation for export | UL certificate + component traceability |

By following this disciplined approach, the result is a rugged, globally certified photocell sensor or outdoor light sensor switch ready for deployment in street lighting, parking lots, building exteriors and more.

Why Does Certified Wire Matter for International Clients?

Shipping lighting fixtures or controllers to global markets? In North America, Latin America, Middle East & Africa, and Europe, expect regulations, customs inspections, and mark checks. Consider the following key benefits:

- Fast customs clearance & inspections– Having a UL Listed product and UL-certified internal components simplifies audit & clearance.

- Reduced risk of return / re-work– A wiring failure is a warranty nightmare; certified wiring makes life easier for specifiers and contractors.

- Demonstration of safety commitment– Many governmental procurement contracts now require not just product listing but traceable components (wire, connectors, base).

- Compliance with differing regional standards– North America (UL or cUL), Latin America (S-mark or IEC/UL equivalency), Middle East & Africa (ESMA, G-mark), Europe (CE + internal safety traceability).

Global compliance snapshot

منطقة | Typical requirement |

North America (USA/Canada) | UL Listed, cUL, component traceability |

أوروبا | CE Mark + EN/IEC standards; internal wiring traceability |

Middle East & Africa (MEA) | ESMA or local mark; documentation often required for wiring |

أمريكا اللاتينية | S-mark, sometimes IEC/UL equivalence; quality assurance focus |

In short: if you specify a “photocell for street light” or “photocell lighting sensor” without verifying that the internal wiring is certified, you run the risk of hidden failures or refused shipments.

Note: Check Long-Join’s North American region certification page for further info.

What Technical Problems Arise Without UL-Certified Wiring?

Here are common issues:

- Insulation breakdown– Sub-standard PVC may degrade with UV or heat, exposing conductors.

- Flame propagation– Without proper flame retardant rating, wiring may contribute to fire risk inside the fixture.

- Voltage or current stress failure– Low-grade wire may not handle 277 V AC loads or surge conditions found in outdoor lighting.

- Warranty and safety risk– A wiring failure could cause fixture outage, safety hazard or negation of UL listing.

- Compliance failure on return shipments – Some markets inspect internal components; missing certification can delay clearance.

Table 3: Failure modes – Cause vs. Solution

وضع الفشل | Typical cause | Solution (certified wiring) |

Short-circuit due to insulation | Non-compliant wire or heat exposure | Use UL Style 1015 rated up to 105 °C |

Wire chafing / vibration failure | Poor routing or non-flexible wire | Proper bundling + stranded wire from certified supplier |

Fire spread inside housing | Wiring not flame tested | Flame-resistant, horizontal flame test passed |

Non-compliance at customs | Lack of traceable certification | Provide UL file numbers & component traceability |

Understanding these failure modes helps specifiers, manufacturers and buyers alike recognise that reliable performance starts from the inside—and the easiest way to ensure that is UL-certified wiring.

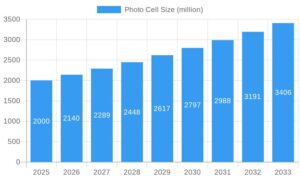

Trend Outlook: Where Are Wiring Standards Going for Photocontrols?

As the lighting industry evolves—smart street light controllers, IoT-connected outdoor lights, remote control light systems—the internal wiring demands become more complex. Consider these emerging trends:

- Multi-core composite cables– Power + communication wires inside one luminaire; each conductor must meet certification.

- Halogen-free, low-smoke insulation– Many projects demand LSOH insulation for underground or enclosed spaces.

- Advanced heat- and UV-resistant jackets– Particularly for highway, desert or high-exposure environments.

- Smaller gauge optimisation– For sensor integration inside a photocell, LED driver, or remote control lighting module.

For manufacturers of a smart “dusk to dawn photocell sensor” or “photocell sensor LED street light”, being ready for these wiring upgrades means staying ahead of market demands. Long-Join is already testing next-gen wiring in partnership with R&D suppliers.

How Do You Verify Wiring Compliance As a Buyer or Specifier?

Here’s a simple checklist you can use:

- Ask for the UL file number or certificateof the internal wire used inside the photocontrol.

- Confirm wire style(e.g., UL Style 1015) and supplier (such as Zhejiang Heye Wire & Cable Co., Ltd with file E527994)

- Request internal wiring diagramshowing routing, bundling, terminals.

- Check product listing: Ensure the complete unit is UL-Listed (e.g., UL 773A for photocontrols) and that component wiring is included in the listing scope.

- Review documentation for export markets: If you ship to Europe/MEA/Latin America, make sure internal wiring traceability is included in compliance documentation.

- On arrival, inspect markings: Look for “STYLE 1015” and appropriate voltage/time/temperature ratings on the wire sheath.

Following this due-diligence ensures your specification of a “photocell lighting control”, “photo sensor switch”, “automatic light sensor” or “outdoor light sensor switch” meets long-term reliability and compliance needs.

خاتمة

While housing materials, PCBs, and connectors often steal the spotlight, it’s the internal wiring that quietly sustains your product’s performance in the field. A top-tier “مفتاح الخلية الضوئية” or “خلية ضوئية لإضاءة الشوارع” may promise many things—but if its internal wiring can’t hold up to heat, vibration, flame or long-term use, you’re vulnerable.

اتصل بـ Long-Join for full component datasheets, UL file numbers, integration guides and wiring diagrams. Let’s build safer, smarter lighting systems together.

الروابط الخارجية:

●https://iq.ul.com/awm/stylepage.aspx?style=1015

●https://www.shopulstandards.com/ProductDetail.aspx?UniqueKey=30530

●https://www.awcwire.com/hook-up-and-lead-wire/pvc-wire/ul-1015?srsltid=AfmBOorEyTyyWDtmEZf-Q_3LjxIPTEwAd05qyacgUq2l030xipl8yn2g

●https://www.esma.europa.eu/

●https://en.wikipedia.org/wiki/Low_smoke_zero_halogen

●https://cableco.com.jo/

https://cnheye.en.alibaba.com/