ما الذي يجعل عناصر التحكم الذكية في الصور "ذكية" حقًا؟

يقدم

Modern street lighting does more than flip on at dusk. It’s also more than shutting off at dawn. Smart lighting systems now have to do more. Old dusk-to-dawn photocell switches are changing. They now act like full lighting controllers.

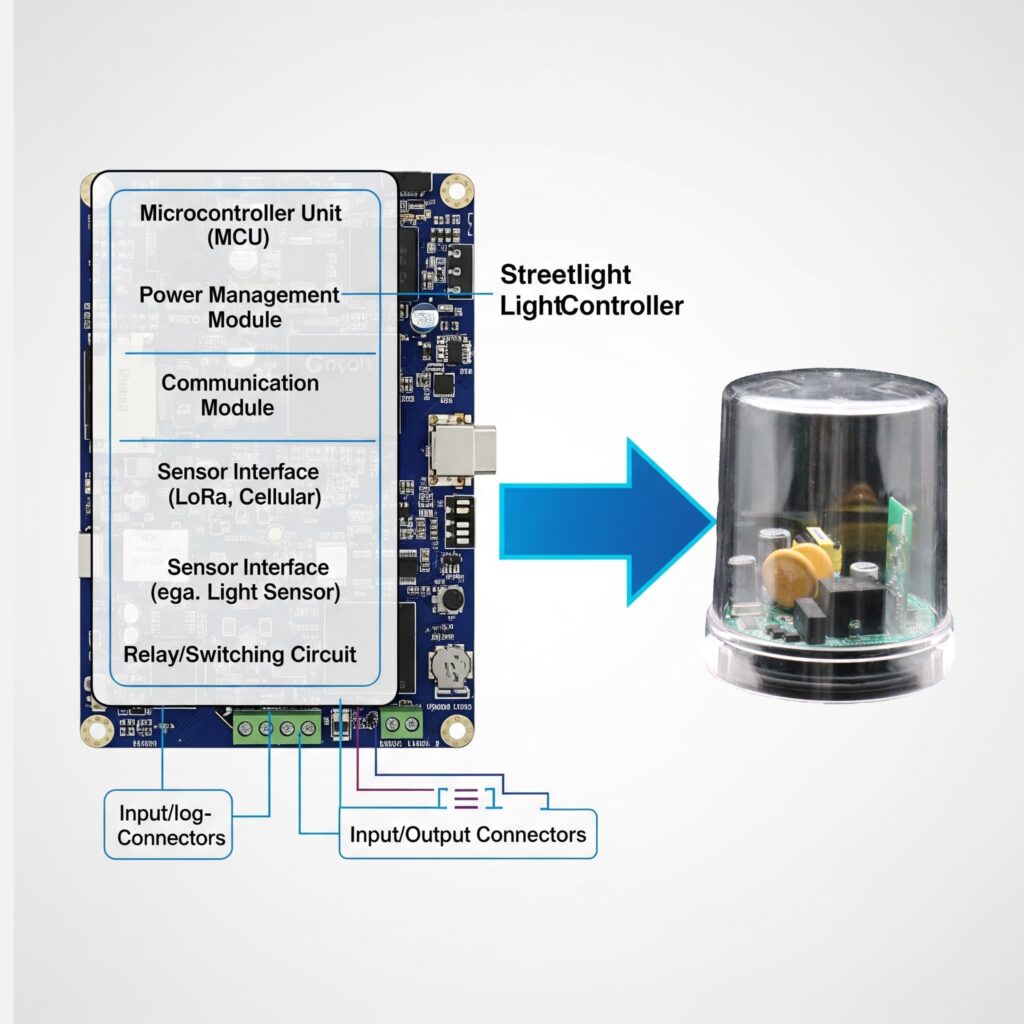

When you plan outdoor lighting for a smart city, a smart campus, or a new LED street light project, you need to see how the system works. The brain (MCU), the link (UART), and the language (Modbus) all have to work as one. Here we unpack what each term means—and how our smart photocontrols deliver flexibility across integration scenarios.

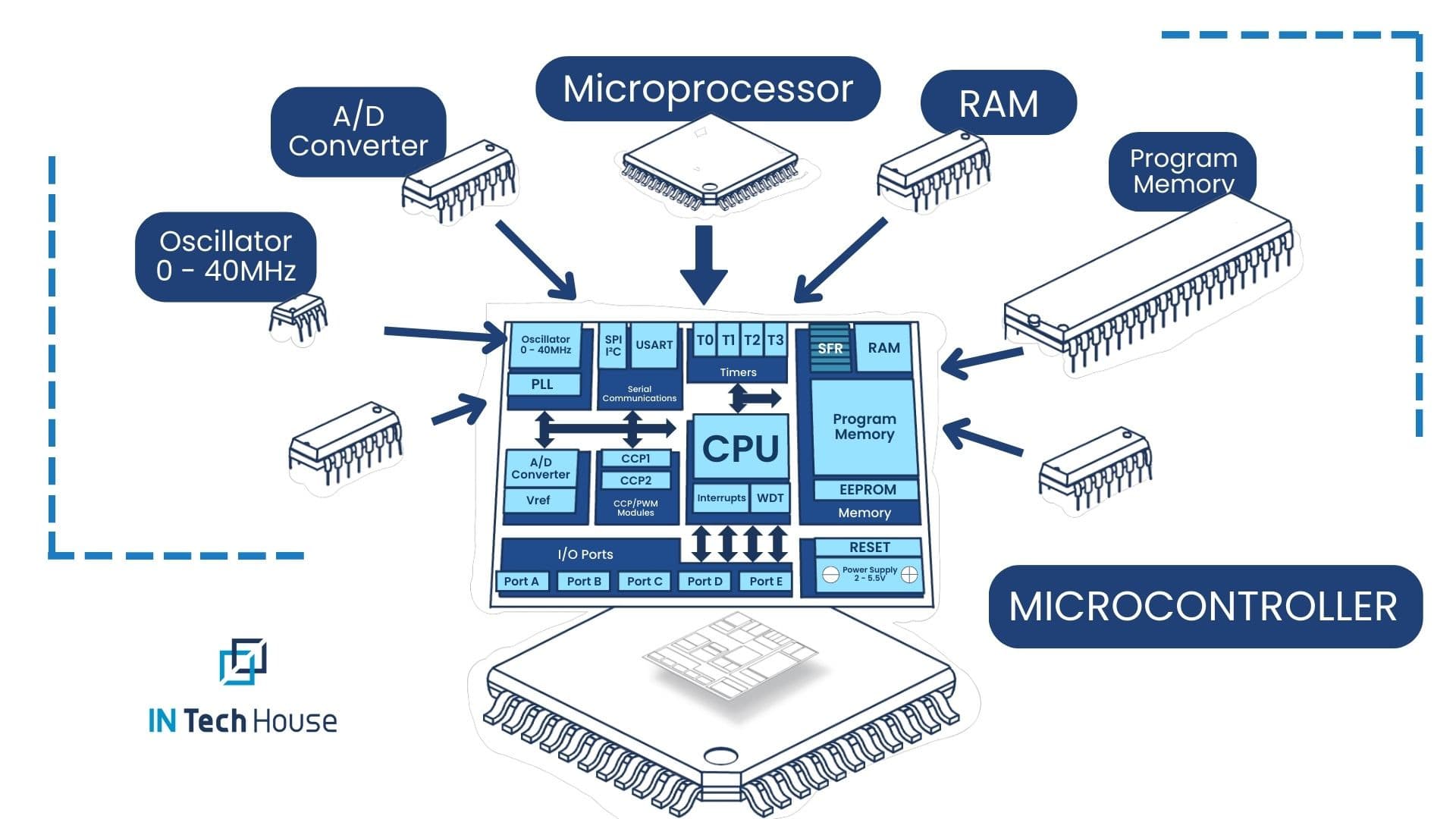

What is an MCU (Microcontroller Unit) and Why Does It Matter in a Photocell Lighting Control?

An MCU – or microcontroller unit – is a compact integrated circuit containing a processor, memory and input/output interfaces.

In the context of a photocell for street light systems:

- The MCU executes lighting-control logic: sensing lux levels, tracking sunrise/sunset, managing delay-off or fault detection.

- It communicates with external devices: sensors, gateways, IoT modules.

- It enables advanced monitoring: load sensing, fault alerting, energy-consumption logging.

In other words: in a “smart” outdoor light sensor switch you go from a passive device (just switching on at low light) to an active controller. The MCU is the edge “brain” inside many modern light sensor photocell switch modules.

Why Many Lighting Manufacturers Are Embedding An MCU

Traditional photocell (analogue) | Smart photocontrol (with MCU) |

Detects ambient light and toggles a relay. | Senses ambient light, monitors load, communicates data, triggers firmware logic. |

No data / limited diagnostics. | Built-in diagnostics, remote commands, energy feedback. |

Stand-alone switching. | Network-connected, part of building or city BMS. |

By integrating an MCU, manufacturers photocell devices no longer act merely as triggers—they become nodes in a connected lighting network.

How Does UART Enable Communication In An Outdoor Photocell Controller?

UART means Universal Asynchronous Receiver/Transmitter. It is a type of serial communication. It’s widely used so one module, like the MCU, can talk to another, like a wireless transceiver, gateway, or communications board.

Key features of UART:

- Two wires (TX = transmit, RX = receive) plus ground.

- Simple for short-range data transfer between circuit boards.

- Structured binary data transfer (hex, bytes) rather than high-level protocols.

So why is UART important in a photocell sensor led street light environment?

- It lets the photocontrol’s internal MCU talk to an external communication board. This board can be a LoRa, NB-IoT, or Zigbee module type.

- It keeps the hardware modular. You can use the same photocell assembly. You only swap the communication module you need.

- It supports firmware updates, diagnostics, and control without redesigning the main board.

Why Is Modbus Used In Smart Lighting Controllers And How Does It Fit With A Photocontrol?

Modbus lets factory devices talk. It was made for PLCs, programmable logic controllers. It sets a common format for data. This includes function codes, register addresses, data length, and checksums.

Why Modbus is relevant in a photocell control or lighting network:

Because of its simplicity and wide support, many manufacturers embed a Modbus interface inside their smart photocontrols so that the device speaks the same “language” as the rest of the building or street-lighting system.

واجهة | حالة الاستخدام النموذجية | الايجابيات | سلبيات |

UART | MCU ↔ comm module (board-level) | Simple wiring, low cost | Point-to-point, smaller ecosystem |

Modbus | Device ↔ BMS/SCADA or network | Standardised, scalable, many field tools | Requires protocol implementation, register mapping |

Thus, in a smart street-lighting rollout the MCU uses UART internally, and exposes a Modbus port externally.

How Does This All Add Up In Our Smart Photocontrol Solutions At Long-Join?

At Long‑Join we bundle the possibilities into two flexible integration modes for our smart photocontrol units:

Integration Mode | وصف |

Customer writes MCU code | We deliver the hardware interface and UART documentation; you programme the control logic. |

Plug-and-play via Modbus | We embed the control logic into an additional MCU on the printed-circuit board assembly (PCBA); you just use Modbus commands to interact with the device. |

This dual approach gives lighting fixture manufacturers, system integrators and city contractors maximum flexibility. You can build your own custom logic—or use a standardised, Modbus-based system and focus on deployment.

Application Notes For Select Models

نموذج | Protocol Support | MCU Logic | تطبيق مناسب |

JL-245CG | UART + Modbus + LoRa/NB-IoT | Embedded MCU | Municipal smart-lighting & data-reporting networks |

JL-ZHGC | UART + Zigbee / WiFi | Built-in control logic | Zhaga-based LED streetlights, intelligent parks |

JL-719WB | UART + Modbus + Cat 1 | MCU optional | High-efficiency urban retrofits with remote control |

What Common Technical Problems Do Smart Photocontrols Solve in Street Lighting?

Problem 1 – Legacy Photocell Cannot Report or Integrate

تقليدي مستشعر الخلايا الضوئية من الغسق إلى الفجر modules simply switch on when ambient light drops. They cannot provide diagnostics, remote commands, or network data. This means cities lose visibility of performance, maintenance becomes reactive, and energy-optimisation is minimal.

Smart units with MCU + UART + Modbus overcome this by giving visibility (faults, load), control (remote off/dim) and connectivity (part of IoT architecture).

Problem 2 – Communication Compatibility and Scalability

When lighting manufacturers integrate smart controls, they face a mix of protocols, legacy wiring, and retrofit constraints. Without a standard interface, each project becomes a custom build. By supporting both UART (internal) and Modbus (external), and thereby offering flexible hardware, a مستشعر إضاءة الخلية الضوئية becomes future-proof and scalable.

Problem 3 – Firmware and Integration Complexity

If the control logic is locked inside a black-box or custom firmware, it becomes costly to update, maintain or integrate. Our dual-mode architecture (option to write your own MCU logic or use our embedded logic with Modbus) lets your team choose the path that fits your business model and integration timelines.

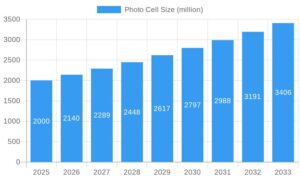

Why “Smart” Matters Now And What Future-Proofing Looks Like?

Street-lighting infrastructure is evolving. According to consultancy reports, as cities modernise networks the ability to monitor, control and collect data from each luminaire becomes a competitive advantage. Standardising on protocols and device architectures reduces risk. By embracing a smart photocell street light module with embedded intelligence, you gain:

- Real-time health monitoring of each luminaire.

- Energy-usage tracking and analytics.

- Remote scheduling, dimming, and fault alerts.

- Easier to connect with city IoT tools and smart-city control systems.

How Do You Pick The Right Smart Photocontrol?

- Does the unit include an MCU that supports logic, sensing and data collection?

- Is the communication interface modular (e.g., UART) so you can choose or upgrade comms?

- Does the device support a field-friendly, widely adopted protocol like Modbus for system integration?

- Can you choose the integration path: build your own logic or use the embedded logic with standard commands?

- Is the solution from a partner manufacturer that provides full documentation, firmware support and roadmap stability?

When you answer “yes” to these questions, you’re choosing a smart photocontrol that delivers more than simply “on/off at dusk”. It becomes a node in a connected lighting network—future-proof, data-enabled and adaptable.

خاتمة

في لونج-جوين، هدفنا بسيط: تمكين المصنّعين والمُدمجين من بناء أنظمة إضاءة خارجية أكثر ذكاءً بأقل جهد. سواءً كنتَ تُنفّذ تحديثًا لإضاءة شوارع البلدية أو مشروع إضاءة ذكي لحديقة جامعية، فإنّ تصميم وحدة التحكم المناسب يُحدث الفرق.

Ready to explore? We offer custom UART/Modbus documentation, OEM/ODM services, MCU firmware support—and we’re here to help you make the lighting network the connected backbone of your infrastructure.

الروابط الخارجية:

●https://en.wikipedia.org/wiki/Microcontroller

●https://en.wikipedia.org/wiki/SCADA

●https://www.synopsys.com/glossary/what-is-a-battery-management-system.html

●https://en.wikipedia.org/wiki/Internet_protocol_suite