Why UK Photocell Bases Look Different From US Versions

導入

When you begin designing a photocell for the UK market, one thing becomes clear very fast: the UK version of a NEMA photocell does not look or behave the same way as the US version. The shape, the lens, the gasket, the pin length, even the brand space — each element follows its own engineering logic.

These differences are not just about appearance. They come from UK luminaire structure, weather patterns, and maintenance habits. Understanding these details helps manufacturers and OEM partners avoid compatibility issues and create better long-life products.

Below is a full engineering breakdown written in a question-and-answer structure, with clear explanations and simple language suited for a young technical reader — while maintaining the professional tone expected from ロングジョイン.

Why Do UK Photocells Use Dome or Prism-Shaped Lenses?

Many engineers notice something right away when comparing photocell designs: UK photocells often have a rounded dome lens or a prism-cut lens, while the US versions usually keep a flatter top. Why?

Does the Dome Shape Help During Rain?

Yes. The UK has long wet seasons, frequent mist, and constant drizzles. A flat lens can trap a thin layer of water, and that small film is enough to confuse a photocell sensor. It may think “night has come,” even when the sun is still up.

A dome lens fixes this because water slides off immediately.

How Dome vs Flat Lenses Behave in Rain

Lens Type | Water Behavior | Impact on Sensor |

Flat Lens | Forms water film easily | Can cause false turn-on |

Dome Lens | Water rolls off quickly | More stable light reading |

This is one reason UK cities prefer dome lenses for street lighting outdoor systems.

Do Prism Lenses Reduce Stray Light Interference?

Yes. UK streets often have shop signs, LED boards, buses with bright displays, and reflective windows. A prism-cut lens scatters unwanted light, keeping the photo sensor focused on natural daylight instead.

This reduces:

- Unexpected flickering

- Early turn-off

- Late turn-on

It keeps the photocell street light more stable in busy environments.

Does the Dome Lens Improve the Sensing Angle?

Most UK luminaires have deeper top housings. A flat lens can sit too low inside the housing, limiting the viewing angle. A dome raises the light sensor high enough to “see” the sky properly.

Without this, the photocell may misread the environment.

Is the Dome Look Part of UK Market Tradition?

Very much. UK contractors expect dome-top photocells. Changing that shape may lead to doubts about quality or compatibility. That is why UK brands continue using this design even as technology evolves.

Why Do UK Photocell Bases Need Longer Copper Pins?

Another major difference between UK and US photocells is the length of the copper terminals inside the photocontrol receptacle. UK versions often need longer pins.

Do Deeper Luminaires Affect Pin Length?

Yes. Many UK street lights use deeper top covers and double-layer structures. Short pins may not reach the terminals inside the luminaire, causing:

- No power flow

- Intermittent power

- Loose locking height

- Random flickering

The copper pin length becomes a key part of stable lighting control.

Copper Pin Issues Caused by Short Pins

問題 | What It Looks Like in the Field |

No Contact | Street light stays off |

Weak Contact | Flickering during night |

Misalignment | Photocell sits uneven after locking |

For OEM partners, pin length is one of the first items to check when designing a photocell for street light systems.

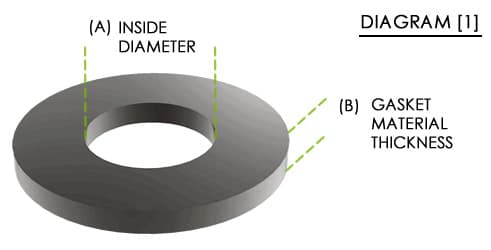

Why Are UK Gaskets Usually 5–6 mm Thick?

US photocells often use 2–3 mm gaskets. But for the UK, 5–6 mm is normal. This is not an accident — it solves a very specific engineering challenge.

Do UK Luminaires Apply More Pressure on the Gasket?

Yes. UK fixtures usually clamp the photocell tighter, and the sealing area faces higher compression. A thin gasket may flatten too much and lose its shape.

A 5–6 mm gasket absorbs this pressure without tearing or shifting.

Does a Thick Gasket Improve IP Protection?

Yes. Many UK manufacturers target IP65–IP66 sealing.

A thick gasket helps prevent:

- Water paths

- Side leakage

- Misalignment of the optical window

- Pressure-related damage

This is one area where UK photocells cannot copy US designs directly.

Gasket Thickness Comparison

地域 | Typical Thickness | 理由 |

US | 2–3 mm | Lower housing pressure |

UK | 5–6 mm | Higher pressure + IP65 needs |

Why Is the Logo Area So Important on UK Bases?

Brand visibility matters in every market, but UK lighting companies treat this even more seriously.

Why Do UK Bases Have a Defined Curved Logo Panel?

Because many UK brands want the photocell to match their existing product line exactly. The logo area is curved, and the shape is often unique. OEMs expect this curve to remain the same when they order new batches.

Can Branding Interfere With Date Marking?

Yes. UK models require clear space for installation date stickers. Engineers must avoid placing logos where the sticker needs to go.

This is why bases such as 224B and 214B have separate zones — one for the brand, one for the date sticker.

Does the Logo Affect Market Trust?

Absolutely. UK contractors look for known shapes and label placements. If the photocell base looks unfamiliar, they may question its fit or quality. Keeping a consistent appearance helps maintain reliability.

Why Does the UK Prefer Sticker Date Marking Over Molded Date Rings?

The US often uses a molded date ring for internal traceability. But the UK rarely accepts this.

Is the Molded Date Ring Useful for Installers?

Not really. Molded dates only show when the product was made — not when it was installed.

In UK municipal projects, the installation date is more important because it determines:

- Warranty

- Maintenance cycles

- Replacement schedules

Why Is a Sticker Better for UK Lighting Maintenance?

Because the installer can write the exact installation date. UK maintenance teams follow strict asset-tracking systems. A sticker supports these systems perfectly.

Molded vs Sticker Date Ring

特徴 | Molded Date Ring | Sticker Date Mark |

Shows production date | はい | はい |

Shows installation date | いいえ | はい |

Replaceable | いいえ | はい |

Preferred in UK | いいえ | はい |

This is why UK photocells rarely include molded date rings on the base.

Can UK Photocells Use US-Style Structures?

Short answer: No. The mechanical form factor is completely different.

What Makes UK and US Designs Incompatible?

Because the engineering philosophy changes from top to bottom:

- Dome lenses → Reduce water film & improve angle

- Prism lenses → Reduce stray light interference

- Longer copper pins → Fit deeper luminaires

- Thick gaskets → Handle stronger compression

- Custom logo zones → Match brand requirements

- Sticker date marks → Follow UK maintenance workflow

Trying to use a US photocell in UK housing often leads to misalignment, sealing failure, or faulty readings.

What Happens If You Install the Wrong Structure?

You may see:

- Flickering lights at night

- Water inside the lens

- A tilted photocell

- A poor lock-in grip

- Wrong turn-on / turn-off times

These failures cost time and money during field repairs, especially for public lighting projects.c

How Can Long-Join Support Your UK Photocell Development?

If you are planning to build or upgrade a UK-style photocell, Long-Join offers the engineering support needed to match every detail.

What Can We Provide for OEM/ODM Partners?

- Custom dome and prism lens designs

- Fully compatible 224B / 214B bases

- Correct copper pin length for UK luminaires

- 5–6 mm precision-cut gaskets

- Dedicated curved logo areas

- Installation date sticker layout

- Fast samples in 3–7 days

- Full testing for UK environmental conditions

You can explore more about photocell engineering and sockets here:

These links help manufacturers compare interface options before choosing the right path.

結論

UK photocells look different from US versions for real engineering reasons. Dome lenses fight water. Prism lenses block stray light. Long pins fit deeper fixtures. Thick gaskets protect against pressure. Clear branding and installation stickers help with maintenance.

Understanding these differences helps lighting brands avoid costly field failures and build photocells that last through tough UK weather.

And with Long-Join’s support, OEM partners can create stable, accurate, and long-life 光電セル照明センサー solutions tailored to UK needs.

外部リンク:

●https://www.hallsigns.com/signs/date-stickers/?srsltid=AfmBOoq5MtZBCj2DQ69lItm-vK6kkfthzckLoN7tei5G7eQkrEylMLp6

●https://www.budind.com/blog/2014/02/the-mysteries-of-ip65-ip66-and-ip67-rated-enclosures-explained/

●https://www.szthreeup.com/-mold-date-inserts/